Five products, one platform – industry solutions powered by CONTACT Elements

Customer Success Stories

BASF Polyurethanes has been using CIM Database since 1994 as a platform for integrated product lifecycle management. When planning and managing development projects and designing new production plants, BASF's synthetics experts benefit from reliable processes and agile teamwork.

Read success storyMANN+HUMMEL is a global leader in the field of filtration. The group uses CIM Database to manage projects at approximately 50 locations worldwide and relies on powerful multi-CAD data management, materials management and BOM management. The specialist has also extensively digitalized its project management: CONTACT's hybrid methodology makes it possible to respond quickly to new market requirements by combining agile methods and conventional management.

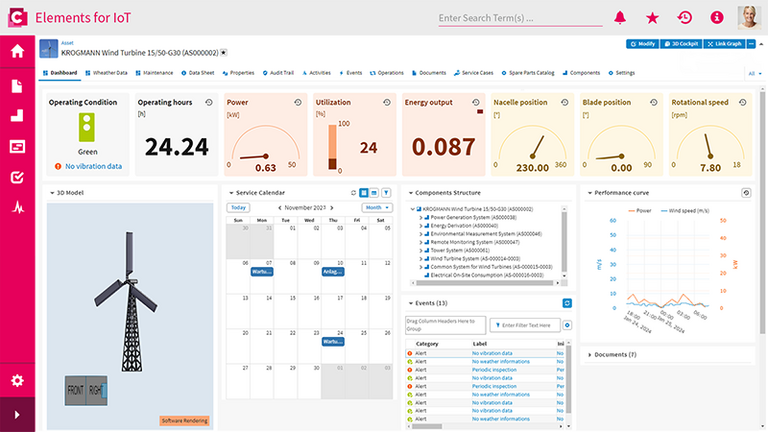

Read success storyThe camshaft specialist thyssenkrupp Dynamic Components develops innovative solutions for the powertrain as a partner to automotive manufacturers. The global market leader ensures seamless PLM processes with CIM Database and real-time production control with CONTACT Elements for IoT. The goal of the Powertrain division of the globally renowned German conglomerate is to increase productivity along the industrial value chain and to expand its position as a leading technological automotive supplier.

Read success story

"CONTACT’s approach to digital threads based on CONTACT Elements’ open web architecture, configurable data model, and composable reusable components enables companies to break down silos and connect their data and processes across the product lifecycle from concept through life."

Mark Reisig, CIMdata 2024, on CONTACT as enabler for digital threads

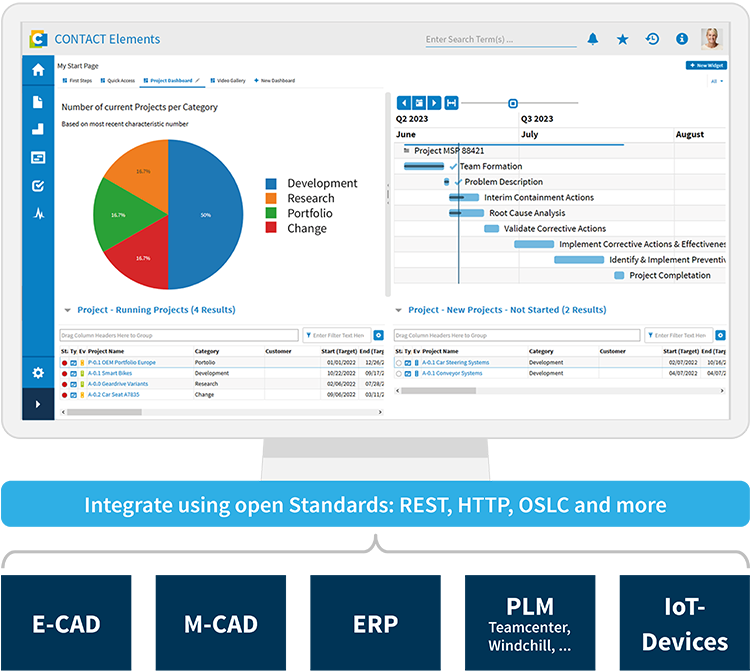

Modular instead of monolithic

Use new building blocks faster and make updates productive earlier

Open interfaces instead of vendor lock-in

Use leading open source software and connect different systems more easily

Configuration instead of programming

Implement your own solutions more agilely in the low-code platform and maintain them more easily

Connecting data and processes end-to-end

Break down data silos and ensure interoperability along the digital thread