Make model geometry available at every workstation!

3D models are becoming increasingly important in companies, especially as part of the visual validation of decisions in the product development process. However, only a few employees have direct access to 3D data – primarily due to the high licensing costs of CAD systems. To overcome this bottleneck, many companies rely on viewers from CAD software providers. This approach is extremely inefficient due to the lack of integration of stand-alone viewers in PLM processes. With CONTACT's 3D Connect, you make model geometry an integral part of your processes, available at every workstation.

Benefits

- Better processes with model data at the push of a button

- Visual analyses and decisions with the 3D Cockpit

- Comfortable sharing of model data for team collaboration

- Easy handling of model data with 3D PDF, JT and STEP

- Digital mock-ups accelerate product validation

Improve your processes with end-to-end geometry information

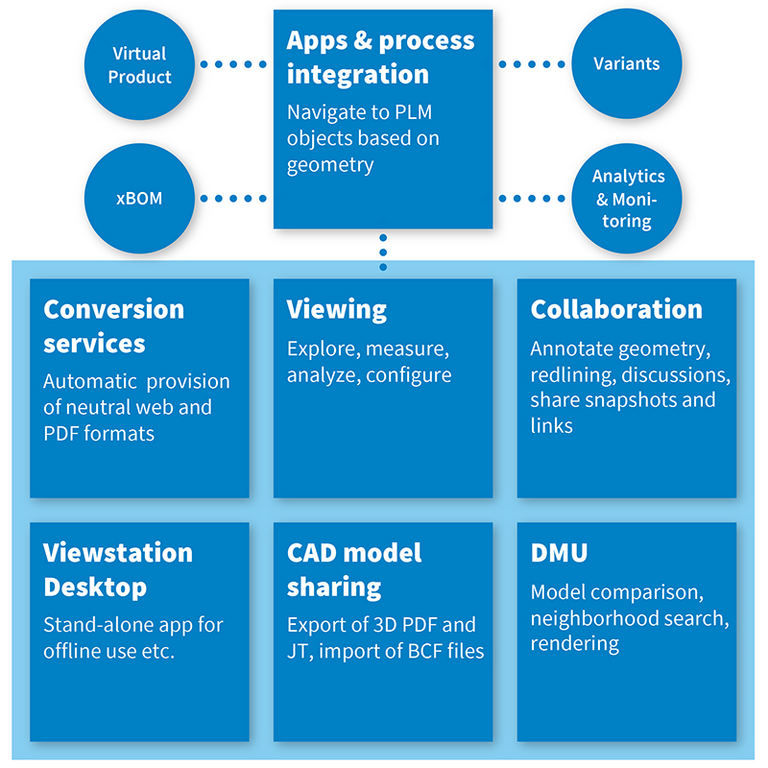

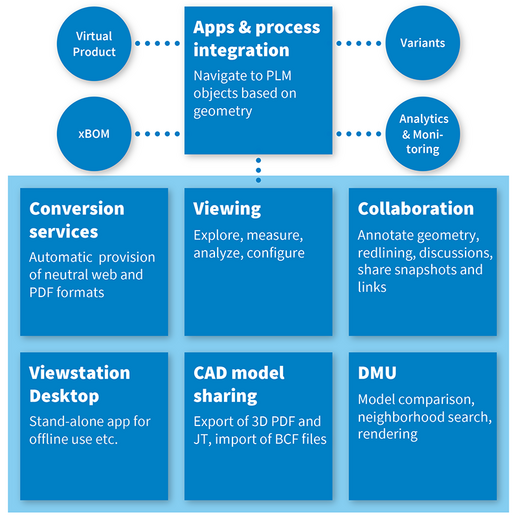

With 3D Connect, you can use 3D models without a CAD system or a separate viewer to simplify visualization and analysis tasks. 3D Connect broadly disseminates geometric information and makes processes more efficient: Through customer documentation and online publishing (PIM), for example as 3D PDF with illustrated BOMs, through the evaluation of engineering changes based on redlinings in the model, through digital mock-ups (DMU) for earlier design validation and much more.

Improve your processes with end-to-end geometry information

With 3D Connect, you can use 3D models without a CAD system or a separate viewer to simplify visualization and analysis tasks. 3D Connect broadly disseminates geometric information and makes processes more efficient: Through customer documentation and online publishing (PIM), for example as 3D PDF with illustrated BOMs, through the evaluation of engineering changes based on redlinings in the model, through digital mock-ups (DMU) for earlier design validation and much more.

With 3D Connect, you can use 3D models without a CAD system or a separate viewer to simplify visualization and analysis tasks. 3D Connect broadly disseminates geometric information and makes processes more efficient: Through customer documentation and online publishing (PIM), for example as 3D PDF with illustrated BOMs, through the evaluation of engineering changes based on redlinings in the model, through digital mock-ups (DMU) for earlier design validation and much more.

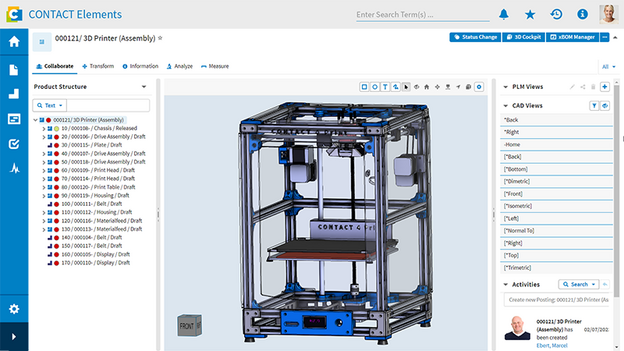

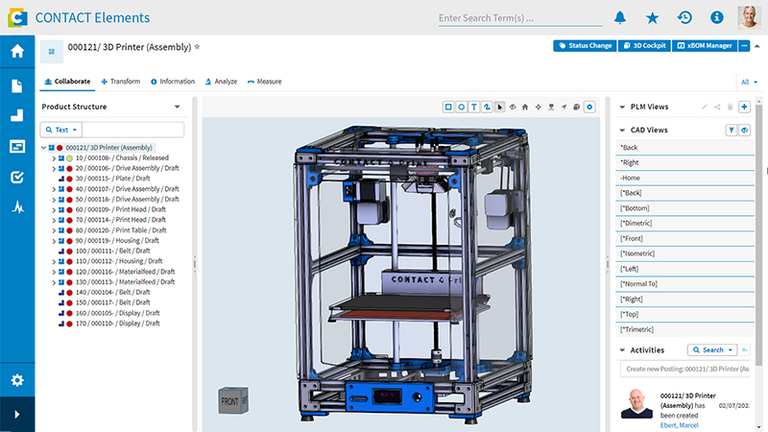

Validate your decisions using the 3D Cockpit

3D Connect is seamlessly integrated with CONTACT Elements and CIM Database PLM. Users directly access CAD model data, parts, variants, product structures and BOMs in the 3D context. The 3D Cockpit is the central tool for intuitive navigation through model and product structures. You can use measurement functions, exploded views and redlining, save snapshots of selected views and use color coding to mirror component properties such as release status directly in the model.

Validate your decisions using the 3D Cockpit

3D Connect is seamlessly integrated with CONTACT Elements and CIM Database PLM. Users directly access CAD model data, parts, variants, product structures and BOMs in the 3D context. The 3D Cockpit is the central tool for intuitive navigation through model and product structures. You can use measurement functions, exploded views and redlining, save snapshots of selected views and use color coding to mirror component properties such as release status directly in the model.

3D Connect is seamlessly integrated with CONTACT Elements and CIM Database PLM. Users directly access CAD model data, parts, variants, product structures and BOMs in the 3D context. The 3D Cockpit is the central tool for intuitive navigation through model and product structures. You can use measurement functions, exploded views and redlining, save snapshots of selected views and use color coding to mirror component properties such as release status directly in the model.

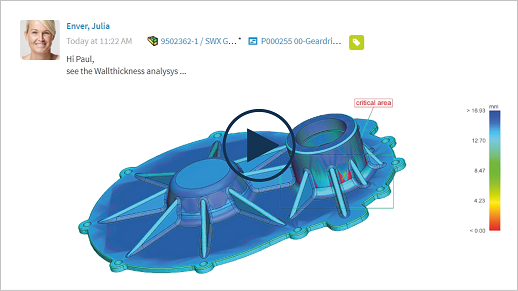

Share model data for high-performance team collaboration

With 3D Connect, users share model data and analysis results directly in the process: visual part information, red markups, comments, notes, views, and more. For example, use our messenger service Activity Streams to suggest changes, discuss variants, and evaluate designs in dialog based on models and redlining. Central processes such as technical changes become faster – internal coordination and collaboration with customers and suppliers can be organized highly efficiently with the support of 3D Connect!

Share model data for high-performance team collaboration

With 3D Connect, users share model data and analysis results directly in the process: visual part information, red markups, comments, notes, views, and more. For example, use our messenger service Activity Streams to suggest changes, discuss variants, and evaluate designs in dialog based on models and redlining. Central processes such as technical changes become faster – internal coordination and collaboration with customers and suppliers can be organized highly efficiently with the support of 3D Connect!

With 3D Connect, users share model data and analysis results directly in the process: visual part information, red markups, comments, notes, views, and more. For example, use our messenger service Activity Streams to suggest changes, discuss variants, and evaluate designs in dialog based on models and redlining. Central processes such as technical changes become faster – internal coordination and collaboration with customers and suppliers can be organized highly efficiently with the support of 3D Connect!

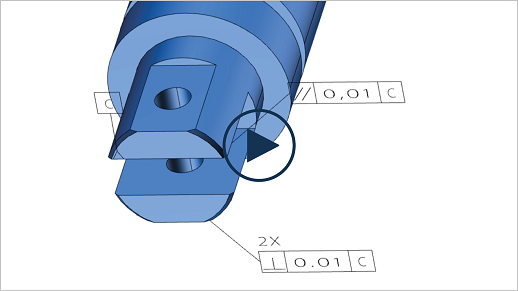

Easy handling of model data with 3D PDF, JT and STEP

3D PDF combines product models with the possibilities of Office documents. The handling of model data becomes as easy as dealing with texts and images. You can display product manufacturing information (PMI) and model views defined in the CAD system. Combined with document templates and form elements, you can link model information with metadata and even interactive operational elements directly in PDF. BOM entries become associative, mirroring the selection of 3D components in the BOM and vice versa. And you can easily share PDF, JT, and STEP files without limits!

3D PDF combines product models with the possibilities of Office documents. The handling of model data becomes as easy as dealing with texts and images. You can display product manufacturing information (PMI) and model views defined in the CAD system. Combined with document templates and form elements, you can link model information with metadata and even interactive operational elements directly in PDF. BOM entries become associative, mirroring the selection of 3D components in the BOM and vice versa. And you can easily share PDF, JT, and STEP files without limits!

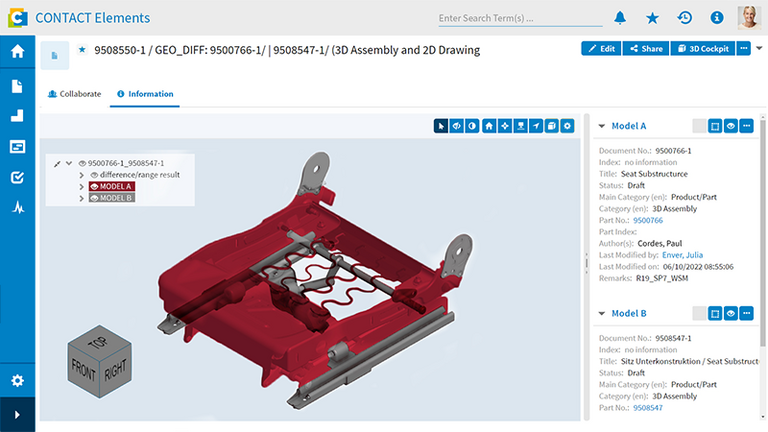

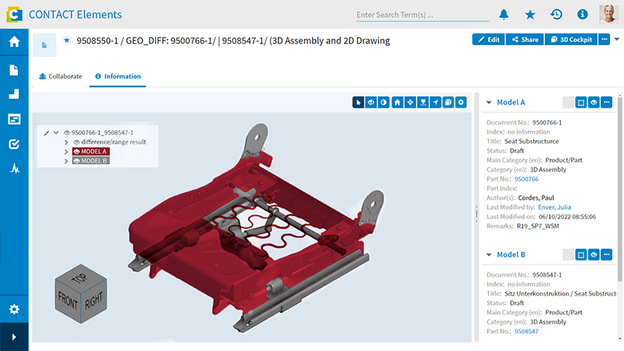

Accelerate product validation with DMU

3D Connect integrates DMU technologies from invenio, the world's leading digital mock-up specialists. Use Clash & Clearance to determine all parts that fall below minimum distances. Analyze collisions, contact surfaces and distance bands in geometry models. Compare model alternatives and supplied variants more easily. Benefit from these high-end DMU functions at every workstation without media discontinuity, high set-up times and time-consuming changes of work context.

Accelerate product validation with DMU

3D Connect integrates DMU technologies from invenio, the world's leading digital mock-up specialists. Use Clash & Clearance to determine all parts that fall below minimum distances. Analyze collisions, contact surfaces and distance bands in geometry models. Compare model alternatives and supplied variants more easily. Benefit from these high-end DMU functions at every workstation without media discontinuity, high set-up times and time-consuming changes of work context.

3D Connect integrates DMU technologies from invenio, the world's leading digital mock-up specialists. Use Clash & Clearance to determine all parts that fall below minimum distances. Analyze collisions, contact surfaces and distance bands in geometry models. Compare model alternatives and supplied variants more easily. Benefit from these high-end DMU functions at every workstation without media discontinuity, high set-up times and time-consuming changes of work context.

Offline and high-performance viewing

Business users with special requirements, for example in the area of wall thickness analysis and for offline operation, benefit from the additional use of the dedicated Kisters ViewStation solution and maintained 3D Connect integration for CONTACT Elements and CIM Database PLM. ViewStation offers special analysis and authoring functions and is particularly suitable for on-site work at the customer's site, even without access to the PLM server services.

Offline and high-performance viewing

Business users with special requirements, for example in the area of wall thickness analysis and for offline operation, benefit from the additional use of the dedicated Kisters ViewStation solution and maintained 3D Connect integration for CONTACT Elements and CIM Database PLM. ViewStation offers special analysis and authoring functions and is particularly suitable for on-site work at the customer's site, even without access to the PLM server services.

Business users with special requirements, for example in the area of wall thickness analysis and for offline operation, benefit from the additional use of the dedicated Kisters ViewStation solution and maintained 3D Connect integration for CONTACT Elements and CIM Database PLM. ViewStation offers special analysis and authoring functions and is particularly suitable for on-site work at the customer's site, even without access to the PLM server services.

Related Elements

Easier team communication with social media features

Targeted information distribution with contextual reference

Tailored delivery of information across the entire company

Encourage employees with a new user experience

Manage CAx data and incorporate changes directly in the development data

Manage your CAx data across different disciplines using an integrated data model

Provide optimum, cross-location support for your product development

Exchange design data seamlessly with partners and customers

Accelerate product development through intelligent management of simulation data and processes

Make simulation processes available company-wide with best practices

Automate processes without programming effort

Save time and reduce errors by integrating the CAD and CAE process chains

Effective frontloading for variable product design

Determine the variability in product management and engineering

Define complete variant models quickly and easily

Supply the correct items, BOMs and model data automatically to downstream processes.

Use DMU models to validate products early, fast and cost-effectively

High-end DMU functions at every workstation

Validate technical changes with automated geometry comparisons

Collision calculations for optimal decisions on variant-specific geometry

High-quality image data for documentation or marketing directly from CAD models

Further information

Would you like to find out more about this topic? Choose one of the following information offers.