Benefits

- Optimal master data organization with universal classification system

- Transparency in parts inventory and less maintenance effort

- Speed up the development process and support systems engineering

- Reduce parts diversity and costs

- Support part search visually

Improve the organization of your master data with an extremely powerful classification system

Master data organization is one of the key tasks of product development. It makes use of various methods that categorize product data and/or information objects in object categories or higher-level class systems. Universal Classification provides you with a powerful mechanism for the characteristics-based organization not just of parts but of all data objects. Group together articles, components and modules as well as documents, products, projects and references systematically in characteristics-based classes and optimize the transparency of your data.

Reduce data maintenance effort with characteristics inheritance

Classify your data objects into groups of similar or associated characteristics within a hierarchically structured characteristics catalog. At the same time, characteristics inheritance ensures uniform naming within a class hierarchy. This cuts the time you need for data maintenance, reduces redundancies and improves the efficiency of characteristics-based search queries.

Master data organization is one of the key tasks of product development. It makes use of various methods that categorize product data and/or information objects in object categories or higher-level class systems. Universal Classification provides you with a powerful mechanism for the characteristics-based organization not just of parts but of all data objects. Group together articles, components and modules as well as documents, products, projects and references systematically in characteristics-based classes and optimize the transparency of your data.

Reduce data maintenance effort with characteristics inheritance

Classify your data objects into groups of similar or associated characteristics within a hierarchically structured characteristics catalog. At the same time, characteristics inheritance ensures uniform naming within a class hierarchy. This cuts the time you need for data maintenance, reduces redundancies and improves the efficiency of characteristics-based search queries.

Support Model-based Systems Engineering effectively

With CONTACT Elements Universal Classification, you lay the foundation for innovative development methods such as Model-based Systems Engineering (MBSE): Universal Classification enables the functional classification of product data and thus feature-driven product development ‒ an essential element of MBSE. Intelligently grouped, your developers will find parts - for example, fasteners made of a specific material ‒ as well as associated documents and projects in no time when defining the solution space and modeling product variability.

Comprehensive support for MBSE methodologies with different views

Universal Classification supports MBSE particularly effectively with flexible representation options: You can represent parts according to functional, logical, physical-geometric or other characteristics in different views ‒ and thus comprehensively support the model-driven methodologies of MBSE.

With CONTACT Elements Universal Classification, you lay the foundation for innovative development methods such as Model-based Systems Engineering (MBSE): Universal Classification enables the functional classification of product data and thus feature-driven product development ‒ an essential element of MBSE. Intelligently grouped, your developers will find parts - for example, fasteners made of a specific material ‒ as well as associated documents and projects in no time when defining the solution space and modeling product variability.

Comprehensive support for MBSE methodologies with different views

Universal Classification supports MBSE particularly effectively with flexible representation options: You can represent parts according to functional, logical, physical-geometric or other characteristics in different views ‒ and thus comprehensively support the model-driven methodologies of MBSE.

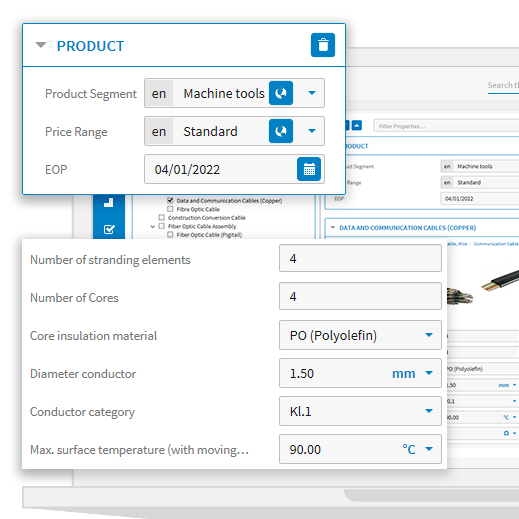

Reduce parts variety and costs and benefit from visual support when searching for parts

Parts classification using class lists of characteristics (CLC) is a proven standard based on DIN 4000/4001/4002. This involves mapping characteristics – e.g., functional, geometrical and physical – using characteristics groups. Your developers can make use of the parametric CAD integration to derive components directly from templates in the CAD system based on the characteristic values of classified articles taken from the 3D models. If a developer creates a new parts master record together with characteristics, then the associated 3D geometry and drawings are automatically available. Universal Classification provides you with the basis for finding parts as quickly as possible, achieving a high reuse rate, reducing parts diversity, and thus lowering purchasing and storage costs.

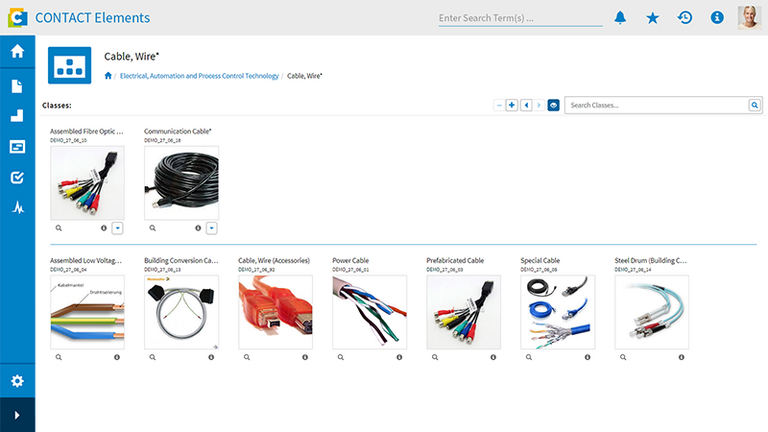

Quickly navigate through parts inventory with visual Class Browser

The visual display of classifying data is another "parts search accelerator". As an alternative navigation and search option, the Class Browser accelerates the identification of required parts by intuitively navigating visually through the parts inventory.

Reduce parts variety and costs and benefit from visual support when searching for parts

Parts classification using class lists of characteristics (CLC) is a proven standard based on DIN 4000/4001/4002. This involves mapping characteristics – e.g., functional, geometrical and physical – using characteristics groups. Your developers can make use of the parametric CAD integration to derive components directly from templates in the CAD system based on the characteristic values of classified articles taken from the 3D models. If a developer creates a new parts master record together with characteristics, then the associated 3D geometry and drawings are automatically available. Universal Classification provides you with the basis for finding parts as quickly as possible, achieving a high reuse rate, reducing parts diversity, and thus lowering purchasing and storage costs.

Quickly navigate through parts inventory with visual Class Browser

The visual display of classifying data is another "parts search accelerator". As an alternative navigation and search option, the Class Browser accelerates the identification of required parts by intuitively navigating visually through the parts inventory.

Parts classification using class lists of characteristics (CLC) is a proven standard based on DIN 4000/4001/4002. This involves mapping characteristics – e.g., functional, geometrical and physical – using characteristics groups. Your developers can make use of the parametric CAD integration to derive components directly from templates in the CAD system based on the characteristic values of classified articles taken from the 3D models. If a developer creates a new parts master record together with characteristics, then the associated 3D geometry and drawings are automatically available. Universal Classification provides you with the basis for finding parts as quickly as possible, achieving a high reuse rate, reducing parts diversity, and thus lowering purchasing and storage costs.

Quickly navigate through parts inventory with visual Class Browser

The visual display of classifying data is another "parts search accelerator". As an alternative navigation and search option, the Class Browser accelerates the identification of required parts by intuitively navigating visually through the parts inventory.

Related Elements

Ensure the compliance of materials with industry and regulatory standards such as REACH and RoHS during the development process

Ensure transparency of materials used in products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Efficiently merge, prepare and release product data for publication

Enable customers and partners to access the product portfolio

Automatically merge product data from sources such as ERP and PLM

Publish product information simply and securely

Automatically combine data, text and images to create online and print content

Seamlessly integrate design and operations of smart products

Analyze and evaluate field data for targeted product improvements

Involve customer communities in the ongoing optimization of products

Use best practices such as ticket systems and quality issues for integration into the development process

Manage material information across the enterprise and ensure sustainability

Company-wide availability of detailed information on material properties

Smooth teamwork with reliable material data

Rapid identification of alternative materials

Ensure sustainability and compliance

Further information

Would you like to find out more about this topic? Choose one of the following information offers.