Sustainable production with digital twins

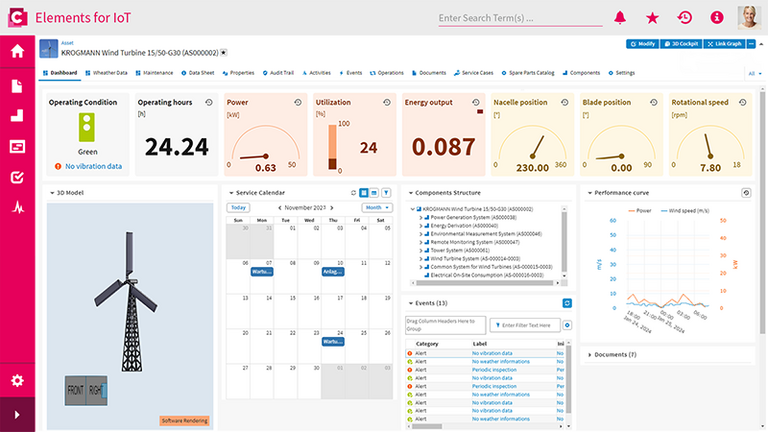

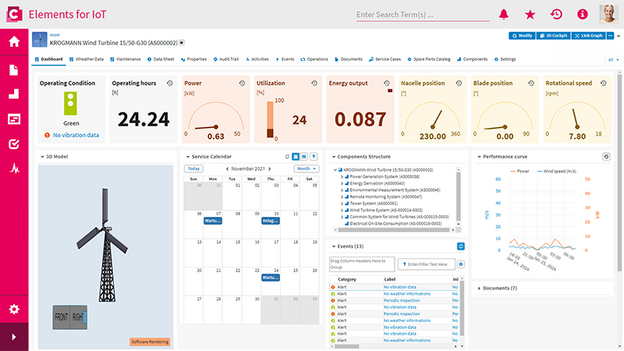

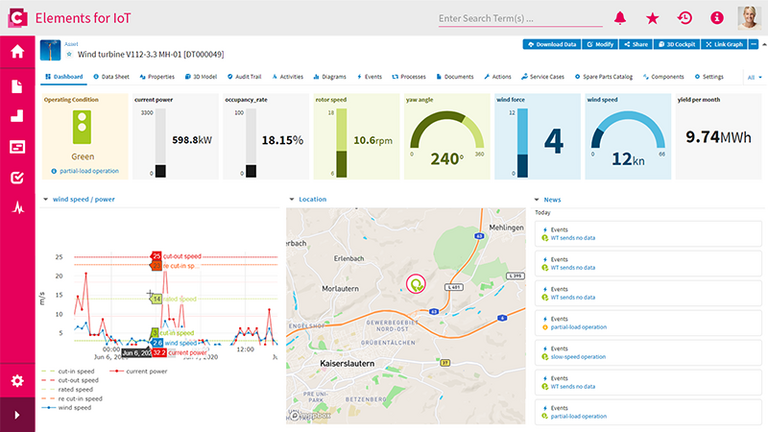

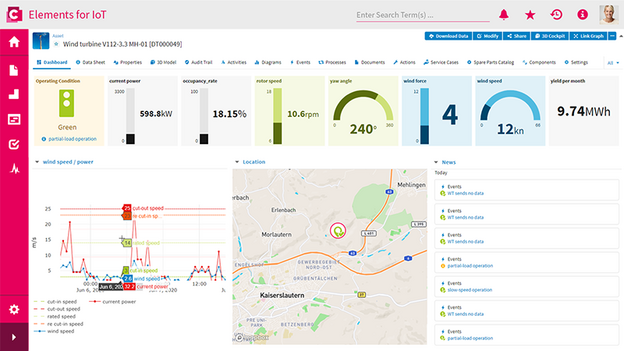

By implementing digital twins of energy-intensive machines and systems, your company creates a foundation for sustainable energy savings. precise virtual mapping allows you to monitor these assets in real time and predict consumption values. You identify inefficient operating phases and optimize your manufacturing processes on this basis. You increase the efficiency of systems with high energy requirements and reduce energy consumption to the minimum.