Driving forward the digitalization of product development – with enterprise-wide accessible DMU functions

The pressure to digitize the product development process is omnipresent today. A central challenge is to digitize an increasing number of tasks from the beginning of the process. The task of product validation is to avoid defective productions, functional deficiencies, and safety risks. Expensive and time-consuming tests with physical prototypes must largely be replaced by digital test models (Digital Mock-ups - DMU). The problem is that for geometric analyses and other DMU tasks, separate DMU tools or CAD-integrated applications are usually only used by a limited group of specialized users and often without integration into data management - which naturally opposes continuous digital processes and widespread DMU usage. CONTACT Elements DMU provides a solution for this: With this component, you can make DMU functions available at every workstation!

Benefits

- High-end digital mockup functions at every workstation

- Validate technical changes with automated geometry comparisons

- Collision calculations for optimal decisions on variant-specific geometry

- High-quality image data for documentation or marketing directly from CAD models

Make high-end digital mockup functions available at every workstation

CONTACT Elements DMU is "powered by" invenio Virtual Technologies, the leading specialist for digital mockups (DMU). Through integration into CONTACT Elements, you can use high-end DMU functions for the model data of all leading CAD systems at every workstation within the product development process. Whether for technical changes, variant management, documentation or marketing − all information relating to digital test models is automatically available without media discontinuity, high set-up times and time-consuming changes of work context.

Make high-end digital mockup functions available at every workstation

CONTACT Elements DMU is "powered by" invenio Virtual Technologies, the leading specialist for digital mockups (DMU). Through integration into CONTACT Elements, you can use high-end DMU functions for the model data of all leading CAD systems at every workstation within the product development process. Whether for technical changes, variant management, documentation or marketing − all information relating to digital test models is automatically available without media discontinuity, high set-up times and time-consuming changes of work context.

CONTACT Elements DMU is "powered by" invenio Virtual Technologies, the leading specialist for digital mockups (DMU). Through integration into CONTACT Elements, you can use high-end DMU functions for the model data of all leading CAD systems at every workstation within the product development process. Whether for technical changes, variant management, documentation or marketing − all information relating to digital test models is automatically available without media discontinuity, high set-up times and time-consuming changes of work context.

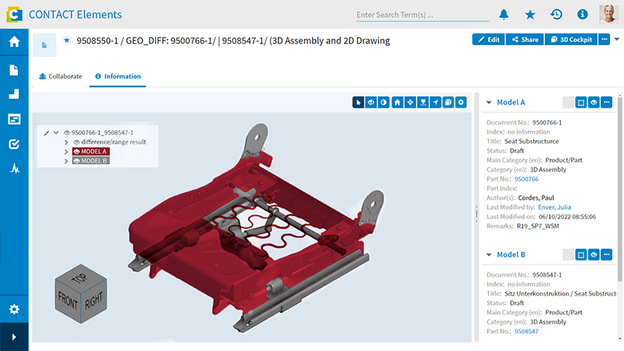

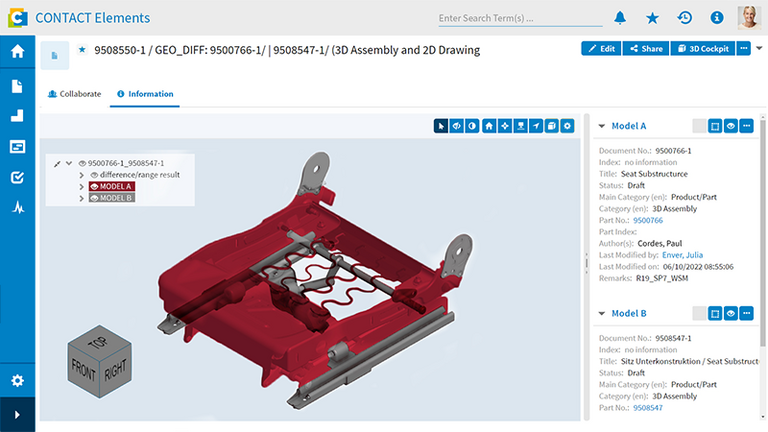

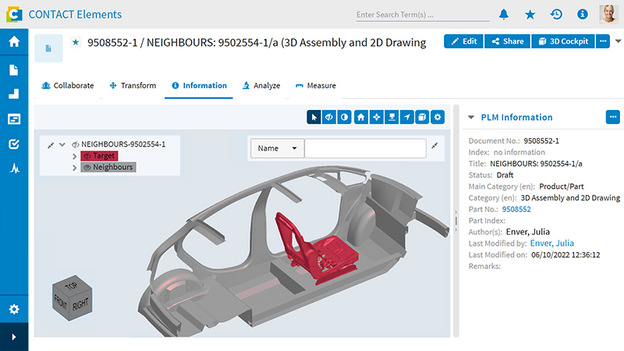

Validate technical changes with automated geometry comparisons

After an engineering change, you can use CONTACT Elements DMU to trigger an automatic geometric comparison of the changed parts. The calculation result is part of the change note as a difference model and is therefore attached to the change folder. Instead of laborious preparation with images in Office documents, you publish the result as a 3D geometric model and make it directly available for subsequent processes such as quality assurance or production.

Validate technical changes with automated geometry comparisons

After an engineering change, you can use CONTACT Elements DMU to trigger an automatic geometric comparison of the changed parts. The calculation result is part of the change note as a difference model and is therefore attached to the change folder. Instead of laborious preparation with images in Office documents, you publish the result as a 3D geometric model and make it directly available for subsequent processes such as quality assurance or production.

After an engineering change, you can use CONTACT Elements DMU to trigger an automatic geometric comparison of the changed parts. The calculation result is part of the change note as a difference model and is therefore attached to the change folder. Instead of laborious preparation with images in Office documents, you publish the result as a 3D geometric model and make it directly available for subsequent processes such as quality assurance or production.

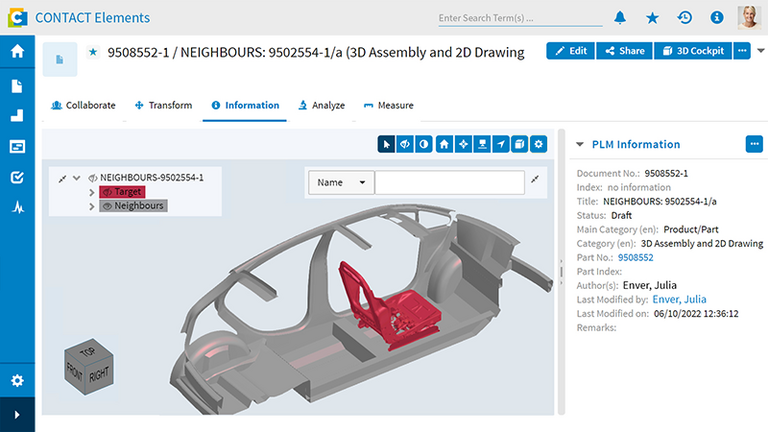

Collision calculations for optimal decisions on geometry variants

In the case of products with many variants, you can use Clash & Clearance to validate changes with regard to their compatibility with the surrounding installation space: The automatic collision calculation of a modified part in its fixtures in a large number of product variants provides certainty here. Recognized problem areas of variant-specific geometry models are uncovered and can be solved directly.

Collision calculations for optimal decisions on geometry variants

In the case of products with many variants, you can use Clash & Clearance to validate changes with regard to their compatibility with the surrounding installation space: The automatic collision calculation of a modified part in its fixtures in a large number of product variants provides certainty here. Recognized problem areas of variant-specific geometry models are uncovered and can be solved directly.

In the case of products with many variants, you can use Clash & Clearance to validate changes with regard to their compatibility with the surrounding installation space: The automatic collision calculation of a modified part in its fixtures in a large number of product variants provides certainty here. Recognized problem areas of variant-specific geometry models are uncovered and can be solved directly.

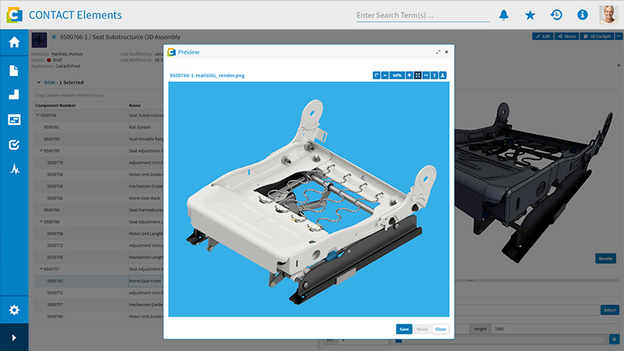

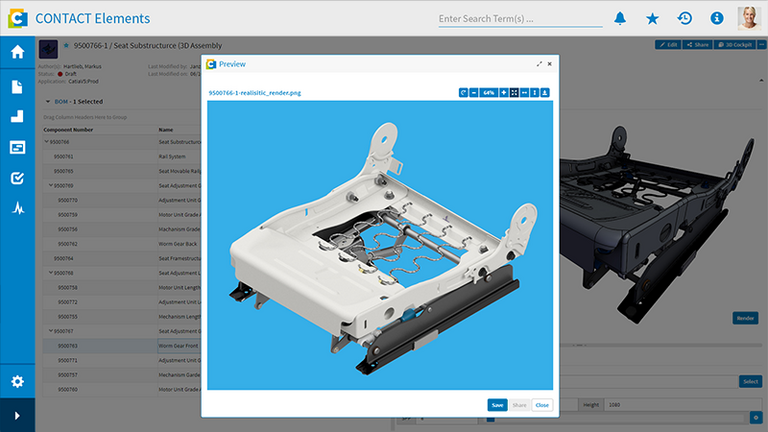

High-quality image data for documentation or marketing directly from CAD models

Based on existing model data, you can automatically generate high-quality image data for technical documentation or marketing and enrich it with information from master data, CAD data management or classification. The results are used in illustrated parts lists in PLM, in Office exports or in enterprise IT such as PIM systems.

High-quality image data for documentation or marketing directly from CAD models

Based on existing model data, you can automatically generate high-quality image data for technical documentation or marketing and enrich it with information from master data, CAD data management or classification. The results are used in illustrated parts lists in PLM, in Office exports or in enterprise IT such as PIM systems.

Based on existing model data, you can automatically generate high-quality image data for technical documentation or marketing and enrich it with information from master data, CAD data management or classification. The results are used in illustrated parts lists in PLM, in Office exports or in enterprise IT such as PIM systems.

Related Elements

Accelerate product development through intelligent management of simulation data and processes

Make simulation processes available company-wide with best practices

Automate processes without programming effort

Save time and reduce errors by integrating the CAD and CAE process chains

3D for everyone! Be better informed and make faster decisions with 3D product data

Better processes with model data at the push of a button

Visual analyses and decisions with the 3D Cockpit

Easier sharing of model data for team collaboration

3D-PDF, JT & STEP: More possibilities with standards

Digital mockups accelerate product protection

Create product architectures and structures efficiently – manage BOMs seamlessly and synchronize them with CAD models

Develop requirements-oriented products

Create mechatronic product structures for systems engineering

Configure variants with 150% BOMs

Manage BOMs and ensuring compliance

Use reliable interfaces between development and production

Planning technical changes reliably, implementing them faster and ensuring traceable documentation

Accelerate change processes through digital workflows and standards

Simplify work with digital folders and Task Manager

Map change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Effective frontloading for variable product design

Consistently determining variability in product management and engineering

Define complete variant models quickly and easily

Direct access to parts, BOMs and model data

Automatically supply downstream processes with the required information

Develop more efficiently across disciplines through better ECAD integration

Further information

Would you like to find out more about this topic? Choose one of the following information offers.