Benefits

- Develop requirements-oriented products

- Create mechatronic product structures for systems engineering

- Configure variants with 150% BOMs

- Manage BOMs and ensuring compliance

- Use reliable interfaces between development and production

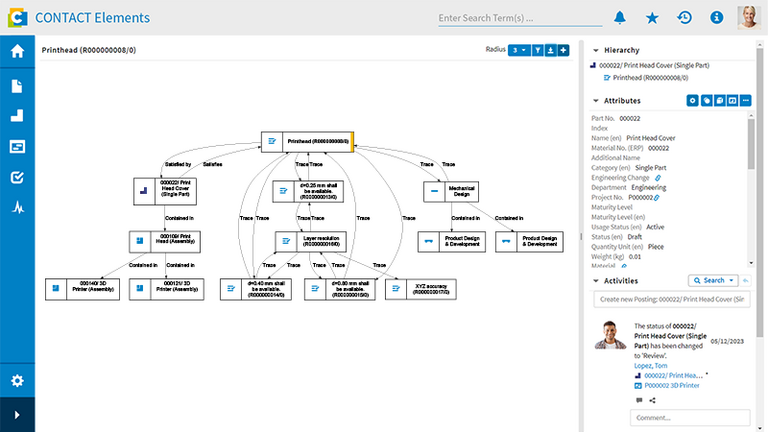

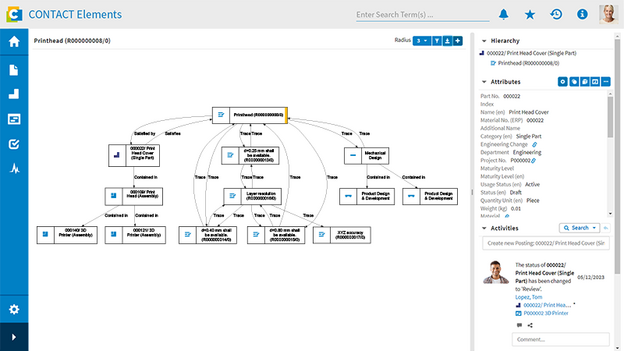

Develop requirements-oriented products

CONTACT's Requirements & Functions allows you to record and process requirements and monitor their fulfillment. This module links requirements with functions, components or tasks, which allows you to control changes and detailed elaboration during the development process directly in the virtual product instead of managing them separately.

Develop in accordance with the V model

CONTACT Elements requirements management capability provides comprehensive support for development in line with the V model for model-based systems engineering (MBSE). This enables you to ensure the transparency of all relationships and dependencies, identify the impact of changes and navigate requirements, functions and product structures with visual support and analyze them more quickly.

Develop requirements-oriented products

CONTACT's Requirements & Functions allows you to record and process requirements and monitor their fulfillment. This module links requirements with functions, components or tasks, which allows you to control changes and detailed elaboration during the development process directly in the virtual product instead of managing them separately.

Develop in accordance with the V model

CONTACT Elements requirements management capability provides comprehensive support for development in line with the V model for model-based systems engineering (MBSE). This enables you to ensure the transparency of all relationships and dependencies, identify the impact of changes and navigate requirements, functions and product structures with visual support and analyze them more quickly.

CONTACT's Requirements & Functions allows you to record and process requirements and monitor their fulfillment. This module links requirements with functions, components or tasks, which allows you to control changes and detailed elaboration during the development process directly in the virtual product instead of managing them separately.

Develop in accordance with the V model

CONTACT Elements requirements management capability provides comprehensive support for development in line with the V model for model-based systems engineering (MBSE). This enables you to ensure the transparency of all relationships and dependencies, identify the impact of changes and navigate requirements, functions and product structures with visual support and analyze them more quickly.

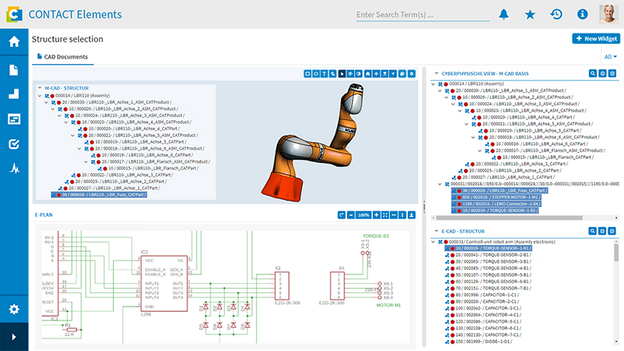

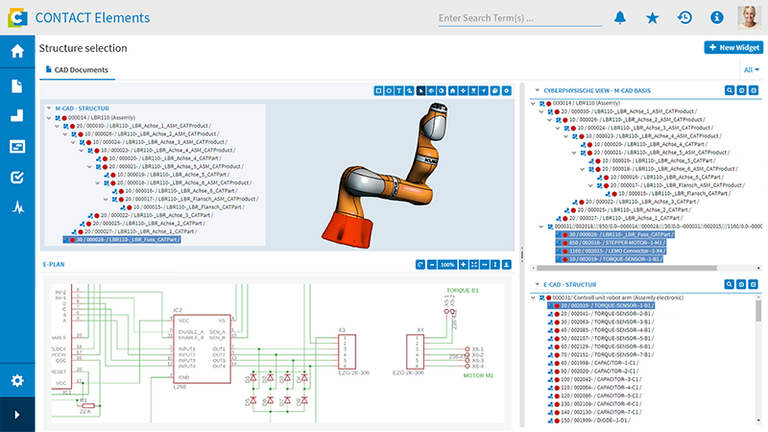

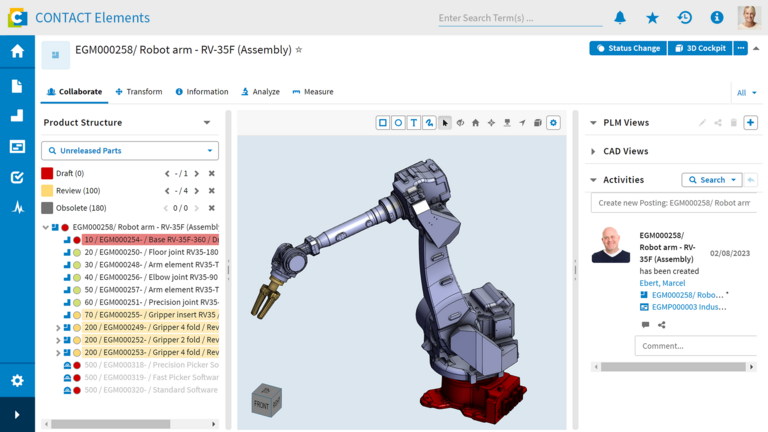

Create mechatronic product structures for systems engineering

Describe products based on their functional product architecture, which incorporates modular elements with concrete technical solutions. Then specify the solution components involving the disciplines mechanical engineering, E/E and software in a common product structure. At the same time, provide support for interfaces to leading CAx tools and state-of-the-art version control systems such as Git and implementations such as GitHub or GitLab in the context of the "software as a part" approach and its processes.

Create mechatronic product structures for systems engineering

Describe products based on their functional product architecture, which incorporates modular elements with concrete technical solutions. Then specify the solution components involving the disciplines mechanical engineering, E/E and software in a common product structure. At the same time, provide support for interfaces to leading CAx tools and state-of-the-art version control systems such as Git and implementations such as GitHub or GitLab in the context of the "software as a part" approach and its processes.

Describe products based on their functional product architecture, which incorporates modular elements with concrete technical solutions. Then specify the solution components involving the disciplines mechanical engineering, E/E and software in a common product structure. At the same time, provide support for interfaces to leading CAx tools and state-of-the-art version control systems such as Git and implementations such as GitHub or GitLab in the context of the "software as a part" approach and its processes.

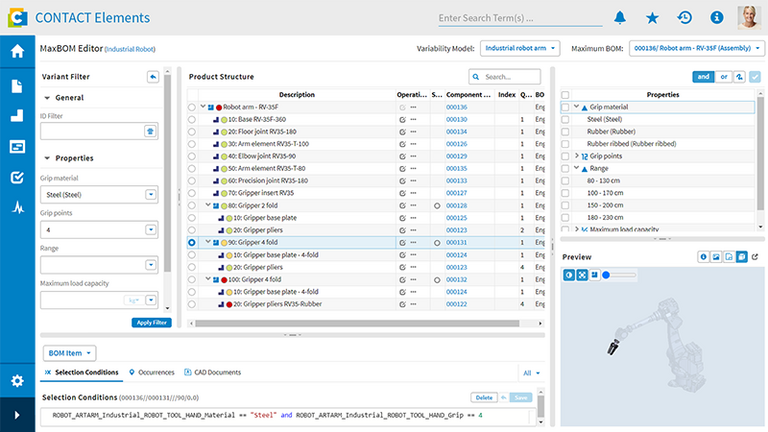

Configure variants with 150% BOMs

Configurable BOMs allow feature-driven development. Benefit from the advantages of efficient variant creation thanks to over-defined maximum BOMs. Perform configuration by entering requirements in the form of values of characteristics and simply select the relevant items from the maximum BOM on the basis of rules. Take advantage of support when configuring 100% components and corresponding CAD model structures.

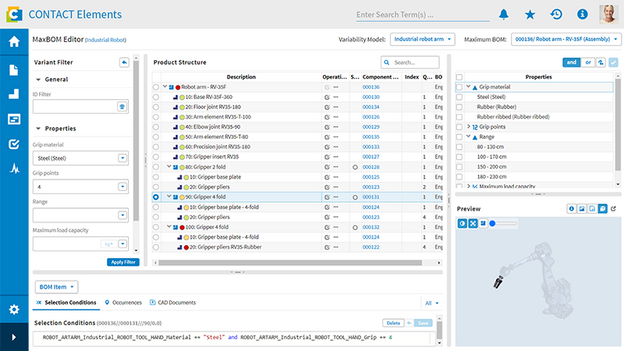

Configure variants with 150% BOMs

Configurable BOMs allow feature-driven development. Benefit from the advantages of efficient variant creation thanks to over-defined maximum BOMs. Perform configuration by entering requirements in the form of values of characteristics and simply select the relevant items from the maximum BOM on the basis of rules. Take advantage of support when configuring 100% components and corresponding CAD model structures.

Configurable BOMs allow feature-driven development. Benefit from the advantages of efficient variant creation thanks to over-defined maximum BOMs. Perform configuration by entering requirements in the form of values of characteristics and simply select the relevant items from the maximum BOM on the basis of rules. Take advantage of support when configuring 100% components and corresponding CAD model structures.

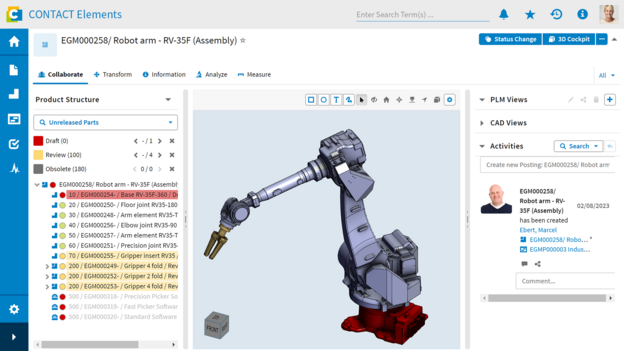

Manage your BOMs and data efficiently and ensure compliance

BOMs contain extensive data such as data on materials and semi-finished products, dimensions, weight and quantities. It forms the starting point for calculating costs, weights and quantities of harmful substances, planning material requirements and much more. CONTACT Elements Product Structure & BOM supports the automatic derivation of this data from CAD model structures, sample structures and 150% BOMs.

Compliance in process guarantees document validity

Cutting down on the number of manual operations involved in maintaining BOMs reduces errors and subsequent costs, for example in your procurement department. In combination with the automatic provision of relevant context information such as models and drawings, you can ensure that a product's documentation fully meets compliance requirements.

Manage your BOMs and data efficiently and ensure compliance

BOMs contain extensive data such as data on materials and semi-finished products, dimensions, weight and quantities. It forms the starting point for calculating costs, weights and quantities of harmful substances, planning material requirements and much more. CONTACT Elements Product Structure & BOM supports the automatic derivation of this data from CAD model structures, sample structures and 150% BOMs.

Compliance in process guarantees document validity

Cutting down on the number of manual operations involved in maintaining BOMs reduces errors and subsequent costs, for example in your procurement department. In combination with the automatic provision of relevant context information such as models and drawings, you can ensure that a product's documentation fully meets compliance requirements.

BOMs contain extensive data such as data on materials and semi-finished products, dimensions, weight and quantities. It forms the starting point for calculating costs, weights and quantities of harmful substances, planning material requirements and much more. CONTACT Elements Product Structure & BOM supports the automatic derivation of this data from CAD model structures, sample structures and 150% BOMs.

Compliance in process guarantees document validity

Cutting down on the number of manual operations involved in maintaining BOMs reduces errors and subsequent costs, for example in your procurement department. In combination with the automatic provision of relevant context information such as models and drawings, you can ensure that a product's documentation fully meets compliance requirements.

Supply ERP and production with reliable data

The automatic and reliable transfer of BOMs to sourcing, process planning and production engineering in the ERP system completes the development. The challenges here are the early scheduling of long-runners in mechanical and plant engineering, the integration of subsequent technical changes and the mapping of logistical concerns such as plant-specific material uses and structures suitable for production or assembly. CONTACT Elements Product Structure & BOM and the xBOM Manager make it possible to master these challenges reliably.

Easier synchronization of engineering and manufacturing BOMs

The mapping of design changes to manufacturing BOMs and other structures such as service, spare parts or maintenance BOMs is a central challenge. With CONTACT's xBOM Manager you support production planning with the fast and secure synchronization of engineering BOMs with manufacturing BOMs and any other structures. In this way, you ensure stable processes and controlled product data at the interfaces between development, production and service.

The automatic and reliable transfer of BOMs to sourcing, process planning and production engineering in the ERP system completes the development. The challenges here are the early scheduling of long-runners in mechanical and plant engineering, the integration of subsequent technical changes and the mapping of logistical concerns such as plant-specific material uses and structures suitable for production or assembly. CONTACT Elements Product Structure & BOM and the xBOM Manager make it possible to master these challenges reliably.

Easier synchronization of engineering and manufacturing BOMs

The mapping of design changes to manufacturing BOMs and other structures such as service, spare parts or maintenance BOMs is a central challenge. With CONTACT's xBOM Manager you support production planning with the fast and secure synchronization of engineering BOMs with manufacturing BOMs and any other structures. In this way, you ensure stable processes and controlled product data at the interfaces between development, production and service.

ON DEMAND WEBCAST

Marel's Digital Highway - a reference case

Learn more about Marel's IT architecture project "Digital Highway"– and thus about next-generation PLM, enterprise architecture integration, and cross-system collaboration and efficient communication.

ON DEMAND WEBCAST

Marel's Digital Highway - a reference case

Learn more about Marel's IT architecture project "Digital Highway"– and thus about next-generation PLM, enterprise architecture integration, and cross-system collaboration and efficient communication.

ON DEMAND WEBCAST

Marel's Digital Highway - a reference case

Learn more about Marel's IT architecture project "Digital Highway"– and thus about next-generation PLM, enterprise architecture integration, and cross-system collaboration and efficient communication.

Related Elements

Manage CAx data and incorporate changes directly in the development data

Manage your CAx data across different disciplines using an integrated data model

Provide optimum, cross-location support for your product development

Exchange design data seamlessly with partners and customers

The easier way from requirements to product

Implement requirements in a comprehensible and function-oriented way

Make use of requirements directly within the project and product context

Link requirements and present a clear overview of interrelationships

Monitor the degree of fulfillment and take corrective action

Accelerate product development through intelligent management of simulation data and processes

Make simulation processes available company-wide with best practices

Automate processes without programming effort

Save time and reduce errors by integrating the CAD and CAE process chains

Effective frontloading for variable product design

Determine the variability in product management and engineering

Define complete variant models quickly and easily

Supply the correct items, BOMs and model data automatically to downstream processes

Fast and reliable synchronization of engineering and manufacturing BOMs

Efficient interaction between development and production planning

Fast and safe elimination of quantity differences

Synchronization with other parts lists for service, spare parts and maintenance

Reliably evaluate deviations directly in the 3D model

Be better informed and make faster decisions with 3D product data

Better processes with model data at the push of a button

Visual analyses and decisions with the 3D Cockpit

Easier sharing of model data for team collaboration

3D-PDF, JT & STEP: More possibilities with standards

Digital mockups accelerate product protection

High-end DMU functions at every workstation Validate technical changes with automated geometry comparisons Collision calculations for optimal decisions on variant-specific geometry High-quality image data for documentation or marketing directly from CAD models

High-end DMU functions at every workstation

Validate technical changes with automated geometry comparisons

Collision calculations for optimal decisions on variant-specific geometry

High-quality image data for documentation or marketing directly from CAD models

Further information

Would you like to find out more about this topic? Choose one of the following information offers.