Resolve the conflict between customer focus and profitability with intelligent variant management

Optimizing the management of diverse product variations and meeting customer needs without escalating complexity and costs is the key challenge in variant management. To address this, your company needs a modular and scalable product architecture, combined with end-to-end data management. CONTACT Elements Variants facilitates this process. It enables strategic portfolio alignment through product platforms, digital organization of data and processes, and efficient, flexible management of variability throughout the product lifecycle. This is how you reconcile the competing demands of customer focus and profitability.

Benefits

- Efficiently and strategically build product portfolios

- Create an ideal balance between customer focus and profitability

- Modularize product variability and manage it consistently throughout the product life cycle

- Maintain transparency and an overview even in complex variant spaces

- Automatically supply subsequent processes with data

Build portfolios strategically and combine customer orientation with cost-efficiency

Powerful variant management is the key to strategically building product portfolios. With CIM Database and the CONTACT Elements Variants module, modular product platforms can be designed easily and flexibly. The intelligent architecture of Variants, combined with digital data and process management, enables highly efficient variant configuration. Using our CTO+ process model, you combine the strengths of Engineer to Order (ETO) and Configure to Order (CTO) – creating the ideal balance between customer-specific solutions and economic efficiency. The result: significantly reduced development effort, largely automated product documentation – and more satisfied customers.

Powerful variant management is the key to strategically building product portfolios. With CIM Database and the CONTACT Elements Variants module, modular product platforms can be designed easily and flexibly. The intelligent architecture of Variants, combined with digital data and process management, enables highly efficient variant configuration. Using our CTO+ process model, you combine the strengths of Engineer to Order (ETO) and Configure to Order (CTO) – creating the ideal balance between customer-specific solutions and economic efficiency. The result: significantly reduced development effort, largely automated product documentation – and more satisfied customers.

Modularize variability and manage it seamlessly across the product lifecycle

With CONTACT Elements Variants, you can build variability models for your platforms and modules based on characteristics and rules. You modularize the variability along the product life cycle, for example by installing products in other products as modules. This consistently model-driven approach creates process reliability and automation potential for subsequent processes. For example, you can automatically generate CAD models of the variants, share the variant parameters with the ERP system and supply the digital twin with the configuration data of each delivered variant.

With CONTACT Elements Variants, you can build variability models for your platforms and modules based on characteristics and rules. You modularize the variability along the product life cycle, for example by installing products in other products as modules. This consistently model-driven approach creates process reliability and automation potential for subsequent processes. For example, you can automatically generate CAD models of the variants, share the variant parameters with the ERP system and supply the digital twin with the configuration data of each delivered variant.

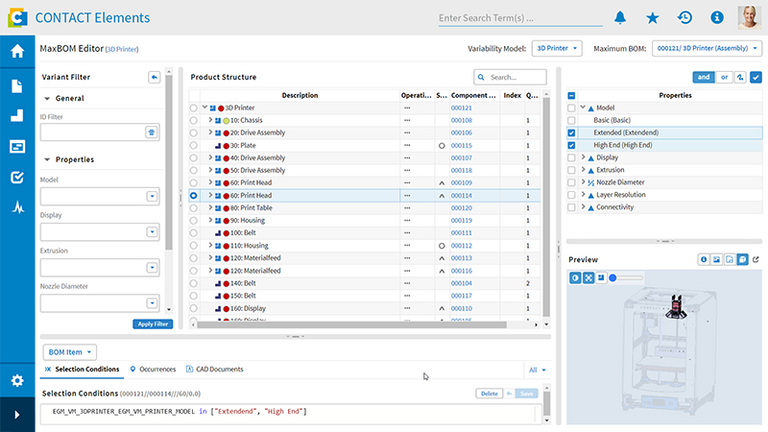

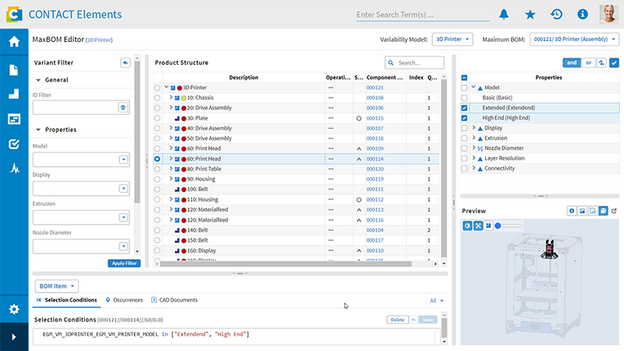

Maintain transparency and clarity even in complex variant spaces

With its dashboards and direct access to all the necessary contextual information, such as the 3D preview, Variants creates outstanding transparency and a clear overview. The focus is on the 150 percent bill of materials and the rule set for determining variants and generating them as articles. The foundation for this is the CONTACT Elements platform with its web-based user interface.

Maintain transparency and clarity even in complex variant spaces

With its dashboards and direct access to all the necessary contextual information, such as the 3D preview, Variants creates outstanding transparency and a clear overview. The focus is on the 150 percent bill of materials and the rule set for determining variants and generating them as articles. The foundation for this is the CONTACT Elements platform with its web-based user interface.

With its dashboards and direct access to all the necessary contextual information, such as the 3D preview, Variants creates outstanding transparency and a clear overview. The focus is on the 150 percent bill of materials and the rule set for determining variants and generating them as articles. The foundation for this is the CONTACT Elements platform with its web-based user interface.

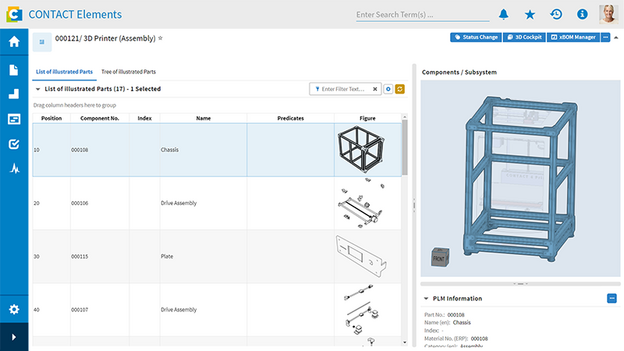

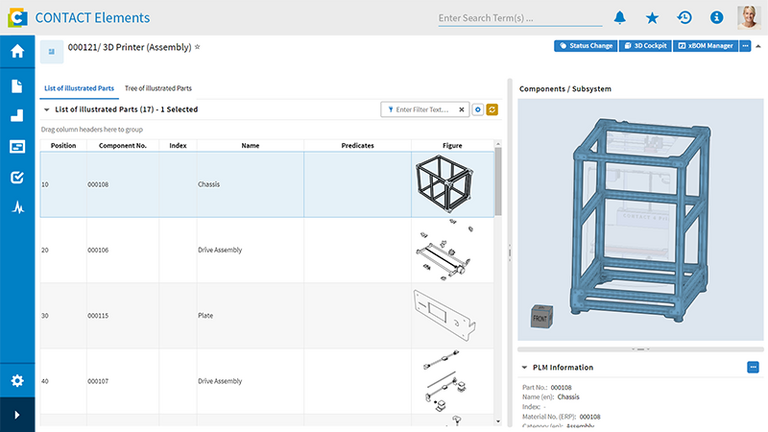

Automatically supply downstream processes with data

Following the detailed configuration and release of a variant, bills of materials, classification data, and image information like illustrated parts lists or digital mock-ups are automatically prepared. This ensures that ERP and CRM systems, CPQ processes for quote generation, online shops for spare parts and accessories, and IoT applications for maintenance always receive up-to-date, error-free data. By automating data provisioning, you minimize manual routine work.

Automatically supply downstream processes with data

Following the detailed configuration and release of a variant, bills of materials, classification data, and image information like illustrated parts lists or digital mock-ups are automatically prepared. This ensures that ERP and CRM systems, CPQ processes for quote generation, online shops for spare parts and accessories, and IoT applications for maintenance always receive up-to-date, error-free data. By automating data provisioning, you minimize manual routine work.

Following the detailed configuration and release of a variant, bills of materials, classification data, and image information like illustrated parts lists or digital mock-ups are automatically prepared. This ensures that ERP and CRM systems, CPQ processes for quote generation, online shops for spare parts and accessories, and IoT applications for maintenance always receive up-to-date, error-free data. By automating data provisioning, you minimize manual routine work.

"With CONTACT Variants, companies can organize their portfolio even more efficiently to offer product variants faster while also reducing costs and complexity due to the increasing number of variants. This capability is critical for companies pursuing configure-to-order (CTO) and engineer-to-order (ETO) strategies. CONTACT believes this solution will help companies go beyond CTO to what they call “CTO+” which includes elements of ETO. Many companies are striving to meet the Industry 4.0 vision and the need to profitably serve markets of one through CTO and ETO strategies. CIMdata believes this essential capability will help CONTACT better serve its demanding customers worldwide."

Stan Przybylinski, Vice President, CIMdata, Inc.

Related Elements

Easier transition from requirements to product

Leverage requirements in the project and product context

Clearly visualize relationships and link requirements

Implement requirements traceably and function-oriented

Track fulfillment progress and implement corrective actions as needed

Manage product and project portfolios with enhanced visibility

Systematic frontloading with the right ideas and initiatives

Structure portfolios for improved clarity

Monitor projects across their entire lifecycle with a single click

Seamlessly integrate design and operations of smart products

Combine PLM and IoT into an innovative closed-loop process

Targeted improvement of products based on operational and usage data

Use tickets and classification to feed field data into the development process

Implement and document technical changes quickly

De-risk products earlier, faster, and more cost-effectively

Empower every workstation with DMU capabilities

Validate technical changes with automated geometry comparisons

Calculate collisions for optimal decisions about variant-specific geometry

Utilize high-quality image data from CAD models for documentation or marketing

Further information

Would you like to know more about this topic? Choose one of the following information offers.