Combining flexibility with process reliability

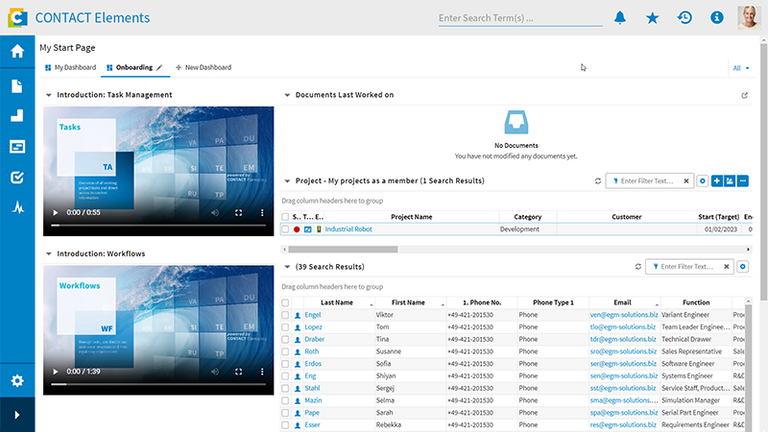

Contemporary CAx data management for companies leaves room for the creativity of employees to develop new ideas in the early design phase. In the more advanced project phases, on the other hand, the requirement comes to the fore to supply subsequent processes in-house as well as partner companies with reliable data and, at the same time, to keep the proportion of routine activities low. CONTACT Elements CAx Document Management optimally supports all project phases of product development.

Benefits

- Reliable data management for all key development tools

- Flexibility and creative freedom in early design phases

- Process-safe availability of results from CAD and CAE systems

- Smooth exchange of design data with partners and suppliers

Reliable data management for leading design tools

MCAD systems such as NX, Catia, Creo, SolidWorks, Solid Edge or Inventor and ePlan, Altium or Mentor for ECAD and EDA form the backbone of design. Their document structures are complex and require intelligent team data management. CONTACT's CAx Document Management meets this requirement by relieving design engineers of routine tasks and at the same time ensuring a process-safe database − with maintained standard interfaces to the leading MCAD and ECAD systems and the most powerful multi-CAD data management on the market.

MCAD systems such as NX, Catia, Creo, SolidWorks, Solid Edge or Inventor and ePlan, Altium or Mentor for ECAD and EDA form the backbone of design. Their document structures are complex and require intelligent team data management. CONTACT's CAx Document Management meets this requirement by relieving design engineers of routine tasks and at the same time ensuring a process-safe database − with maintained standard interfaces to the leading MCAD and ECAD systems and the most powerful multi-CAD data management on the market.

Process-safe availability of models and drawings

Complex products include dozens or even hundreds of models and drawings. They are the decisive basis for subsequent tasks such as procurement, simulation, technical changes, and even the use of the digital twin for service purposes. Intelligent data management means here: The necessary data and models are automatically retrieved, prepared – for example, converted into formats such as 3D PDF – and made available. The manual effort for the employees is almost zero.

Complex products include dozens or even hundreds of models and drawings. They are the decisive basis for subsequent tasks such as procurement, simulation, technical changes, and even the use of the digital twin for service purposes. Intelligent data management means here: The necessary data and models are automatically retrieved, prepared – for example, converted into formats such as 3D PDF – and made available. The manual effort for the employees is almost zero.

Collaborate better − whether within the company or with partners and suppliers

When working with partners and suppliers, it is important to reliably synchronize interim versions and deliverables with your internal data resources throughout the process. Workspaces support your development teams in the early design phase with a high degree of creative freedom. The Collaboration Portal, designed for data exchange with external users, provides tasks and output data securely on the web, informs about interim changes and simplifies the integration of results. Clients thus have full transparency and control!

Collaborate better − whether within the company or with partners and suppliers

When working with partners and suppliers, it is important to reliably synchronize interim versions and deliverables with your internal data resources throughout the process. Workspaces support your development teams in the early design phase with a high degree of creative freedom. The Collaboration Portal, designed for data exchange with external users, provides tasks and output data securely on the web, informs about interim changes and simplifies the integration of results. Clients thus have full transparency and control!

When working with partners and suppliers, it is important to reliably synchronize interim versions and deliverables with your internal data resources throughout the process. Workspaces support your development teams in the early design phase with a high degree of creative freedom. The Collaboration Portal, designed for data exchange with external users, provides tasks and output data securely on the web, informs about interim changes and simplifies the integration of results. Clients thus have full transparency and control!

Related Elements

Be better informed and make faster decisions with 3D product data

Better processes with model data at the push of a button

Visual analyses and decisions with the 3D Cockpit

Easier sharing of model data for team collaboration

3D-PDF, JT & STEP: More possibilities with standards

Digital mockups accelerate product protection

Targeted development of product architectures and structures

Develop requirements-oriented products

Create mechatronic product structures for systems engineering

Configure variants with 150% BOMs

Manage BOMs and ensuring compliance

Use reliable interfaces between development and production

Effective frontloading for variable product design

Consistently determining variability in product management and engineering

Define complete variant models quickly and easily

Direct access to parts, BOMs and model data

Automatically supply downstream processes with the required information

Develop more efficiently across disciplines through better ECAD integration

Accelerate product development through intelligent management of simulation data and processes

Make simulation processes available company-wide with best practices

Automate processes without programming effort

Save time and reduce errors by integrating the CAD and CAE process chains

Proof of concept: Evaluate the benefits through solution scenarios tailored to your needs

Further information

Would you like to find out more about this topic? Choose one of the following information offers.