Improve products, develop variants, and react quickly to new requirements

Product lifecycle management (PLM) and the Industrial Internet of Things (IIoT) offer enormous opportunities for companies today. The exploitation of operational and usage data through an intelligent interaction of PLM and IIoT enables manufacturers to continuously improve their products, develop variants faster, and adapt to new requirements. Companies can use modern approaches to respond to customer needs in a more agile way and meet sustainability mandates. Learn how CONTACT's Closed Loop Engineering can help you leverage a future-oriented method of product development and take your competitiveness to a new level.

Benefits

- Combine PLM and IoT into an innovative closed-loop process

- Targeted improvement of products based on operational and usage data

- Use tickets and classification to feed field data into the development process

- Implement and document technical changes quickly

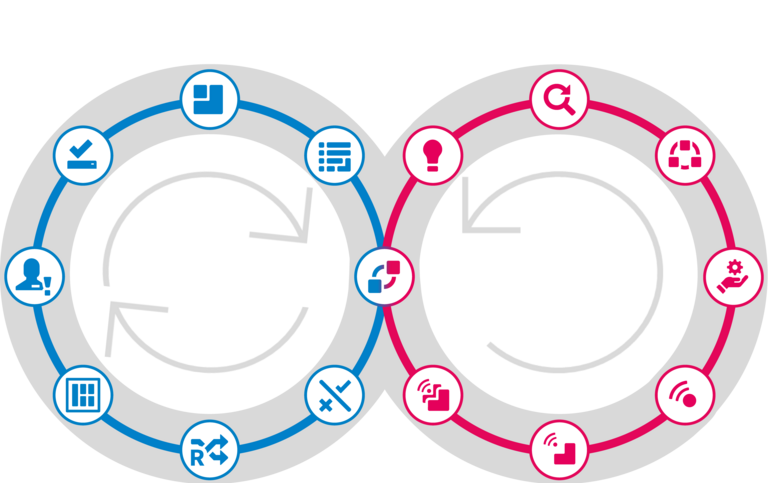

Combine PLM with IoT to create an innovative closed loop process

Closed Loop Engineering represents a new era in product development: Create a highly innovative feedback process that allows data from your own production as well as operational and usage data from the field to flow back into your development. This intelligent marriage of PLM and IoT lets you design, manufacture, and operate products more efficiently and sustainably than ever before. In addition, the automation of processes ranging from development and the shopfloor to service and logistics provides more transparency and increases your value creation.

Combine PLM with IoT to create an innovative closed loop process

Closed Loop Engineering represents a new era in product development: Create a highly innovative feedback process that allows data from your own production as well as operational and usage data from the field to flow back into your development. This intelligent marriage of PLM and IoT lets you design, manufacture, and operate products more efficiently and sustainably than ever before. In addition, the automation of processes ranging from development and the shopfloor to service and logistics provides more transparency and increases your value creation.

Closed Loop Engineering represents a new era in product development: Create a highly innovative feedback process that allows data from your own production as well as operational and usage data from the field to flow back into your development. This intelligent marriage of PLM and IoT lets you design, manufacture, and operate products more efficiently and sustainably than ever before. In addition, the automation of processes ranging from development and the shopfloor to service and logistics provides more transparency and increases your value creation.

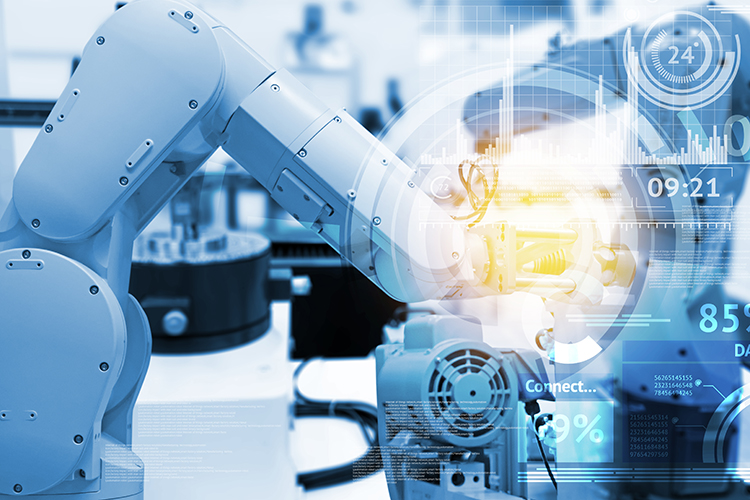

Improve products in a targeted manner on the basis of operating and usage data

Manufacturers are always faced with the challenge of improving products and developing innovative variants. But how can they make informed decisions about product design, functions, or materials? Machines, systems, and other smart products, equipped with sensors, provide valuable data on the use of functions and failure rates of components. Use the insights from data analysis as a solid basis for optimizing new product generations and offering your customers attractive solutions. This is how you score the decisive points in the competition for product innovations.

Improve products in a targeted manner on the basis of operating and usage data

Manufacturers are always faced with the challenge of improving products and developing innovative variants. But how can they make informed decisions about product design, functions, or materials? Machines, systems, and other smart products, equipped with sensors, provide valuable data on the use of functions and failure rates of components. Use the insights from data analysis as a solid basis for optimizing new product generations and offering your customers attractive solutions. This is how you score the decisive points in the competition for product innovations.

Manufacturers are always faced with the challenge of improving products and developing innovative variants. But how can they make informed decisions about product design, functions, or materials? Machines, systems, and other smart products, equipped with sensors, provide valuable data on the use of functions and failure rates of components. Use the insights from data analysis as a solid basis for optimizing new product generations and offering your customers attractive solutions. This is how you score the decisive points in the competition for product innovations.

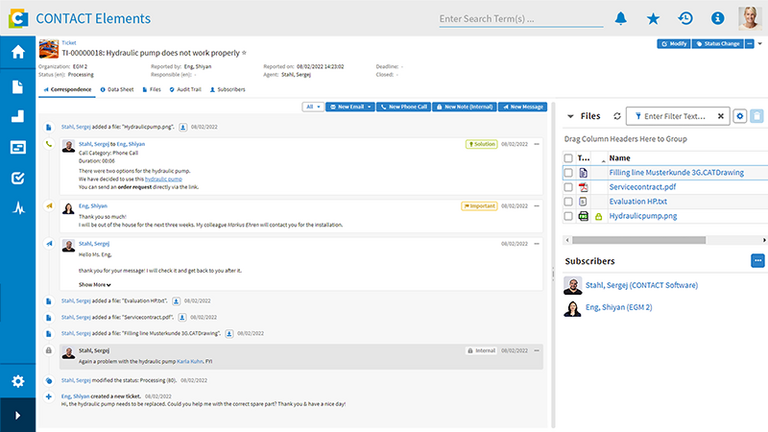

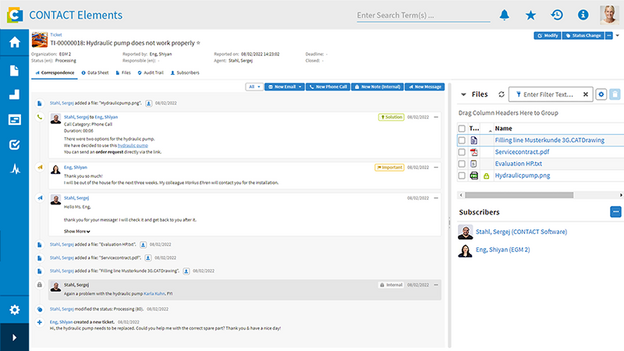

Feed in information into development with tickets and classification

Organize incoming operational and usage data as well as customer concerns with CONTACT Elements' ticketing system. With this technology, you can control information in a targeted manner and assign processes to teams or persons. End-to-end digital processes ensure transparency and documented procedures. In addition, you can use Universal Classification to clearly structure data by products – for example, according to technical requirements, additional product functions, or material variants.

Feed in information into development with tickets and classification

Organize incoming operational and usage data as well as customer concerns with CONTACT Elements' ticketing system. With this technology, you can control information in a targeted manner and assign processes to teams or persons. End-to-end digital processes ensure transparency and documented procedures. In addition, you can use Universal Classification to clearly structure data by products – for example, according to technical requirements, additional product functions, or material variants.

Organize incoming operational and usage data as well as customer concerns with CONTACT Elements' ticketing system. With this technology, you can control information in a targeted manner and assign processes to teams or persons. End-to-end digital processes ensure transparency and documented procedures. In addition, you can use Universal Classification to clearly structure data by products – for example, according to technical requirements, additional product functions, or material variants.

Implement and document technical changes quickly

Accelerate technical changes with the engineering change module from CONTACT Elements. Thanks to digital workflows and templates, you can easily map your change processes and document them automatically. The module enables you to make changes to the order-neutral digital master and the order-specific digital twin separately but linked to each other. With the closed-loop methodology, you can implement new requirements from the field in a targeted manner, document this in the lifecycle file of your products, and continuously improve them.

Accelerate technical changes with the engineering change module from CONTACT Elements. Thanks to digital workflows and templates, you can easily map your change processes and document them automatically. The module enables you to make changes to the order-neutral digital master and the order-specific digital twin separately but linked to each other. With the closed-loop methodology, you can implement new requirements from the field in a targeted manner, document this in the lifecycle file of your products, and continuously improve them.

Related Elements

Turning ideas into successful products

Involve your employees and customers in your innovation initiatives

Use a reliable innovation process and information hub to exploit the full potential of ideas and suggestions

Make well-informed decisions based on systematic evaluations

Control the implementation of ideas in combination with requirements, product and project management.

Record and eliminate complaints and shortcomings in the product context

Improve customer satisfaction and reduce series ramp-up costs

Implement an end-to-end process from the recording of errors to their rectification through to the archiving of solutions

Plan technical changes reliably and implement them faster

Accelerate your change processes through digital workflows and standards

Simplify your employees' work with digital folders and Task Manager

Adapt your change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Classify parts, documents and other objects

Improve the organization of your master data with an extremely powerful classification system

Speed up your development process and support innovative methods such as systems engineering

Use class lists of characteristics to reduce parts variety and costs and benefit from visual support when searching for part

Use IoT data to increase production quality

Using data science and analytics as the basis for data-driven processes

Process large amounts of data automatically

Automate condition monitoring and minimize downtime

Enable complex analyses with templates at the push of a button

Keep assets in view with dashboards and manage them securely with key performance indicators

Further information

Would you like to find out more about this topic? Choose one of the following information offers.