Make materials data management sustainable and flexible − quickly find alternative materials

High raw material prices, a lack of upstream products, and increasing sustainability and compliance requirements are impacting production planning. The industry must make its supply chains more resilient so that the assembly lines do not come to a standstill. At the same time, customers and legislators are paying increasing attention to the lifecycle assessment of products. With Material Data Management, the CONTACT Elements platform offers a new PLM module with which companies can design the management of materials sustainably and flexibly and consistently align it with new requirements such as the rapid identification of alternative materials.

Benefits

- Company-wide availability of detailed information on material properties

- Smooth teamwork with reliable material data

- Rapid identification of alternative materials

- Ensure sustainability and compliance

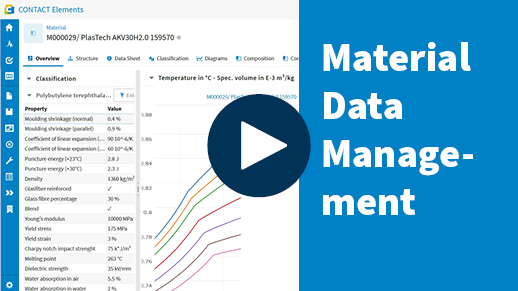

Provide detailed material information across the company

With CONTACT Material Data Management, detailed information on material properties, substances and the material composition of products, analyses and measurement reports are now easily available throughout the company. Through its integration into Product Lifecycle Management (PLM) and simulation management, the central material catalog enables a smooth exchange of information across departments. Status networks and release processes ensure consistent material data and traceable design decisions.

Provide detailed material information across the company

With CONTACT Material Data Management, detailed information on material properties, substances and the material composition of products, analyses and measurement reports are now easily available throughout the company. Through its integration into Product Lifecycle Management (PLM) and simulation management, the central material catalog enables a smooth exchange of information across departments. Status networks and release processes ensure consistent material data and traceable design decisions.

With CONTACT Material Data Management, detailed information on material properties, substances and the material composition of products, analyses and measurement reports are now easily available throughout the company. Through its integration into Product Lifecycle Management (PLM) and simulation management, the central material catalog enables a smooth exchange of information across departments. Status networks and release processes ensure consistent material data and traceable design decisions.

Collaborate better with reliable material data

With CONTACT's Material Data Management, departments and divisions now have direct access to the materials that have been qualified and approved in the laboratory: The design department can thus weigh up different material properties when selecting materials for a component, while the purchasing department checks factors such as availability and prices. Simulation calculates whether selected materials meet product requirements in terms of elasticity or other characteristics, and quality assurance evaluates the materials in terms of sustainability and compliance. In short, company-wide access to consistent materials data ensures smooth and highly efficient teamwork.

Collaborate better with reliable material data

With CONTACT's Material Data Management, departments and divisions now have direct access to the materials that have been qualified and approved in the laboratory: The design department can thus weigh up different material properties when selecting materials for a component, while the purchasing department checks factors such as availability and prices. Simulation calculates whether selected materials meet product requirements in terms of elasticity or other characteristics, and quality assurance evaluates the materials in terms of sustainability and compliance. In short, company-wide access to consistent materials data ensures smooth and highly efficient teamwork.

With CONTACT's Material Data Management, departments and divisions now have direct access to the materials that have been qualified and approved in the laboratory: The design department can thus weigh up different material properties when selecting materials for a component, while the purchasing department checks factors such as availability and prices. Simulation calculates whether selected materials meet product requirements in terms of elasticity or other characteristics, and quality assurance evaluates the materials in terms of sustainability and compliance. In short, company-wide access to consistent materials data ensures smooth and highly efficient teamwork.

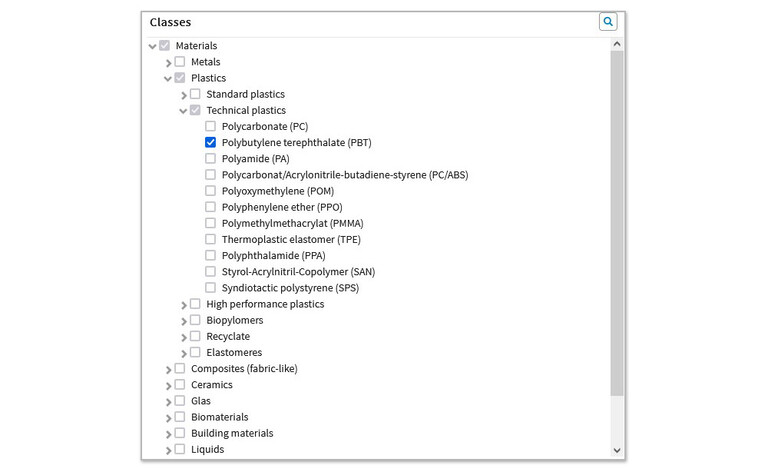

Quickly identify alternative materials

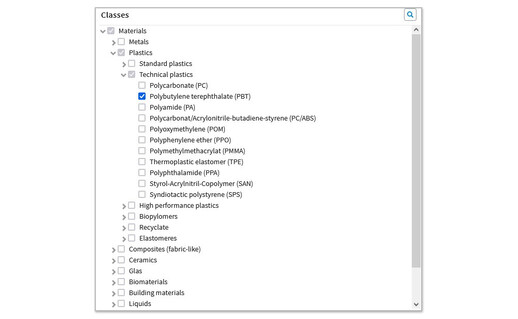

In view of disrupted supply chains, rising raw material prices and growing sustainability requirements, companies today need to be able to identify alternative materials quickly. CONTACT Materials Data Management significantly simplifies and accelerates the search: employees can filter specifically by attributes such as manufacturer, supplier, substances, material properties, or by material classes such as metal or plastic, and select suitable materials in a targeted manner. In addition, the ability to map material information in any breadth and depth and to classify it comprehensively significantly speeds up the search for suitable alternative materials.

Quickly identify alternative materials

In view of disrupted supply chains, rising raw material prices and growing sustainability requirements, companies today need to be able to identify alternative materials quickly. CONTACT Materials Data Management significantly simplifies and accelerates the search: employees can filter specifically by attributes such as manufacturer, supplier, substances, material properties, or by material classes such as metal or plastic, and select suitable materials in a targeted manner. In addition, the ability to map material information in any breadth and depth and to classify it comprehensively significantly speeds up the search for suitable alternative materials.

In view of disrupted supply chains, rising raw material prices and growing sustainability requirements, companies today need to be able to identify alternative materials quickly. CONTACT Materials Data Management significantly simplifies and accelerates the search: employees can filter specifically by attributes such as manufacturer, supplier, substances, material properties, or by material classes such as metal or plastic, and select suitable materials in a targeted manner. In addition, the ability to map material information in any breadth and depth and to classify it comprehensively significantly speeds up the search for suitable alternative materials.

Ensure sustainability and compliance

Integrated material management as part of product data management is essential for sustainable development and product compliance. With CONTACT's Material Data Management and Material Compliance, companies can meet requirements such as obligations for substance certificates and the declaration of materials used with little effort. Likewise, sustainability information can be comprehensively mapped in the digital product files and used for purposes such as Design for Environment (DfE) or the reporting of life cycle assessments.

Ensure sustainability and compliance

Integrated material management as part of product data management is essential for sustainable development and product compliance. With CONTACT's Material Data Management and Material Compliance, companies can meet requirements such as obligations for substance certificates and the declaration of materials used with little effort. Likewise, sustainability information can be comprehensively mapped in the digital product files and used for purposes such as Design for Environment (DfE) or the reporting of life cycle assessments.

Integrated material management as part of product data management is essential for sustainable development and product compliance. With CONTACT's Material Data Management and Material Compliance, companies can meet requirements such as obligations for substance certificates and the declaration of materials used with little effort. Likewise, sustainability information can be comprehensively mapped in the digital product files and used for purposes such as Design for Environment (DfE) or the reporting of life cycle assessments.

Related Elements

Create product architectures and structures efficiently – manage BOMs seamlessly and synchronize them with CAD models

Develop requirements-oriented products

Create mechatronic product structures for systems engineering

Configure variants with 150% BOMs

Manage BOMs and ensuring compliance

Use reliable interfaces between development and production

Classify parts, documents and other objects to improve transparency, speed up processes and reduce parts variety

Optimize the organization of master data with a universal classification system

Speed up the development process and support systems engineering

Use class lists of characteristics to reduce parts variety and costs – use object plans for visual support when searching for parts

Planning technical changes reliably, implementing them faster and ensuring traceable documentation

Accelerate change processes through digital workflows and standards

Simplify work with digital folders and Task Manager

Map change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Ensure the compliance of materials with industry and regulatory standards such as REACH and RoHS during the development process

Ensure transparency of materials used in products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Further information

Would you like to find out more about this topic? Choose one of the following information offers.