Unlocking greater energy efficiency

The industrial sector leads in energy consumption in Germany, accounting for approximately one-third of the country's total energy usage. Faced with escalating energy costs and stringent climate protection regulations, companies are compelled to optimize resource usage and identify potential savings. However, achieving effective and measurable reductions in energy consumption and emissions requires precise knowledge. This necessitates tools and digital solutions to capture, visualize, and optimize data.

CONTACT Elements for IoT enables the implementation of energy management software, facilitating effective energy monitoring through robust features and informative dashboards. Capture energy data, identify energy-intensive assets, and implement targeted efficiency-enhancing measures.

Benefits

- Digitally capture energy consumption

- Monitor energy data with Smart Meter Dashboards

- Uncover potential savings and reduce costs

- Link production and energy data

- Comply with environmental regulations

Sustainable business success with Elements for IoT

Comprehensive energy management

Holistic energy management is imperative for energy-efficient production in manufacturing companies. The integration of production and energy data offers significant potential to optimize manufacturing processes and conserve energy resources. Our comprehensive platform, Elements for IoT, enables reliable real-time data monitoring and analysis of extensive datasets. By seamlessly integrating this data into a comprehensive energy management system, companies can use energy more efficiently, achieve environmental goals, and reduce operating costs.

Comprehensive energy management

Holistic energy management is imperative for energy-efficient production in manufacturing companies. The integration of production and energy data offers significant potential to optimize manufacturing processes and conserve energy resources. Our comprehensive platform, Elements for IoT, enables reliable real-time data monitoring and analysis of extensive datasets. By seamlessly integrating this data into a comprehensive energy management system, companies can use energy more efficiently, achieve environmental goals, and reduce operating costs.

Holistic energy management is imperative for energy-efficient production in manufacturing companies. The integration of production and energy data offers significant potential to optimize manufacturing processes and conserve energy resources. Our comprehensive platform, Elements for IoT, enables reliable real-time data monitoring and analysis of extensive datasets. By seamlessly integrating this data into a comprehensive energy management system, companies can use energy more efficiently, achieve environmental goals, and reduce operating costs.

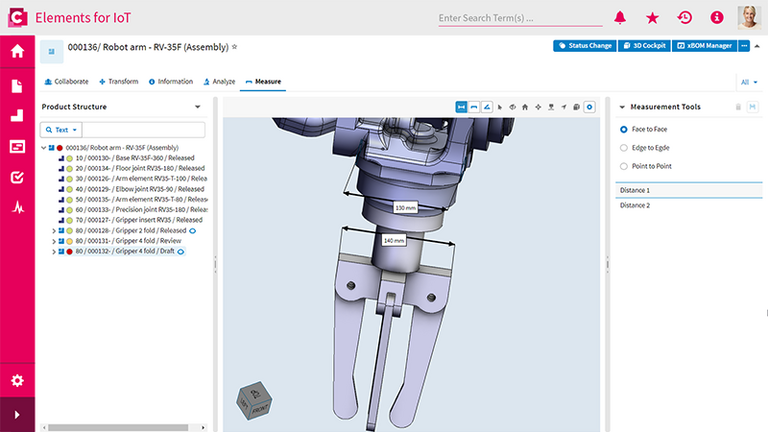

The Digital Twin facilitates energy savings

Implementing a Digital Twin of energy-intensive assets enables sustainable energy savings. The precise replication of real facilities allows for real-time monitoring to identify inefficient operating phases and optimize conditions. Thus, the Digital Twin creates a data-driven foundation for precise decisions, increasing the efficiency of high-energy-consuming facilities and minimizing energy consumption.

The Digital Twin facilitates energy savings

Implementing a Digital Twin of energy-intensive assets enables sustainable energy savings. The precise replication of real facilities allows for real-time monitoring to identify inefficient operating phases and optimize conditions. Thus, the Digital Twin creates a data-driven foundation for precise decisions, increasing the efficiency of high-energy-consuming facilities and minimizing energy consumption.

Implementing a Digital Twin of energy-intensive assets enables sustainable energy savings. The precise replication of real facilities allows for real-time monitoring to identify inefficient operating phases and optimize conditions. Thus, the Digital Twin creates a data-driven foundation for precise decisions, increasing the efficiency of high-energy-consuming facilities and minimizing energy consumption.

All critical energy data at a glance

Meaningful dashboards are particularly helpful when visualizing and analyzing large datasets for quickly gaining an overview. With Elements for IoT, you can create individual dashboards tailored to your information needs, bundling all relevant energy consumption data in a clear manner. These enable a comprehensive analysis of energy efficiency from the production plant to the end product and automate the creation of audit-compliant reports.

All critical energy data at a glance

Meaningful dashboards are particularly helpful when visualizing and analyzing large datasets for quickly gaining an overview. With Elements for IoT, you can create individual dashboards tailored to your information needs, bundling all relevant energy consumption data in a clear manner. These enable a comprehensive analysis of energy efficiency from the production plant to the end product and automate the creation of audit-compliant reports.

Meaningful dashboards are particularly helpful when visualizing and analyzing large datasets for quickly gaining an overview. With Elements for IoT, you can create individual dashboards tailored to your information needs, bundling all relevant energy consumption data in a clear manner. These enable a comprehensive analysis of energy efficiency from the production plant to the end product and automate the creation of audit-compliant reports.

Intelligent energy management for the Smart Factory

Our energy management software uses AI-based analysis methods to help you optimize processes on the shopfloor. By forecasting the energy consumption of machines, for example, you can reduce power consumption to a minimum when processing your production orders. It is also possible to predict peak loads for planned production processes and optimize switch-off times. The recorded consumption data can be used to calculate and continuously update the CO2 footprint of a manufactured product.

Intelligent energy management for the Smart Factory

Our energy management software uses AI-based analysis methods to help you optimize processes on the shopfloor. By forecasting the energy consumption of machines, for example, you can reduce power consumption to a minimum when processing your production orders. It is also possible to predict peak loads for planned production processes and optimize switch-off times. The recorded consumption data can be used to calculate and continuously update the CO2 footprint of a manufactured product.

Our energy management software uses AI-based analysis methods to help you optimize processes on the shopfloor. By forecasting the energy consumption of machines, for example, you can reduce power consumption to a minimum when processing your production orders. It is also possible to predict peak loads for planned production processes and optimize switch-off times. The recorded consumption data can be used to calculate and continuously update the CO2 footprint of a manufactured product.

Energy management with digital twins

With the data from a digital twin, companies can increase the efficiency of energy-intensive production facilities. Especially when they also use AI. In this technical article, Dr Nicole Göckel and Johann Heinrich explain the added value of this combination for energy management in companies based on the example of the research project WindIO.

Energy management with digital twins

With the data from a digital twin, companies can increase the efficiency of energy-intensive production facilities. Especially when they also use AI. In this technical article, Dr Nicole Göckel and Johann Heinrich explain the added value of this combination for energy management in companies based on the example of the research project WindIO.

With the data from a digital twin, companies can increase the efficiency of energy-intensive production facilities. Especially when they also use AI. In this technical article, Dr Nicole Göckel and Johann Heinrich explain the added value of this combination for energy management in companies based on the example of the research project WindIO.