CIM Database PLM has proved its worth in every way as an open platform for our wide-ranging requirements and processes.Benjamin Müller

PLM Project Manager

KIRCHHOFF Automotive

The PLM system for better collaboration and faster processes during product engineering

CIM Database is an open and scalable system for Product Lifecycle Management (PLM). Its key benefits are better collaboration and faster processes in projects and across disciplines, systems and organizations. CIM Database's component architecture simplifies deployment and helps companies respond to new requirements with agility. Thanks to the underlying open platform CONTACT Elements, CIM Database PLM can be easily connected to IoT systems such as our digital twin platform Elements for IoT. This allows you to fully exploit the potential of innovative product development with an end-to-end Digital Thread along the entire lifecycle.

Benefits

- Connect PLM and IoT and leverage the potential of innovative product development

- Encourage collaboration − Share product data and knowledge

- Run PLM processes with best practices quickly and reliably

- Combine project management and processing methodically perfect

- Connect systems for up-to-date data anywhere in the company

Use smart product models along the Digital Thread and connect PLM and IoT

The engine for consistent PLM is the comprehensive model of the virtual product. This allows data and processes to be used digitally from the initial ideas through to release into production. Smart digital models simplify front-loading to make faster decisions and avoid late, costly changes. By enriching PLM data for downstream processes such as manufacturing and operations, you lay the foundation for an intelligent closed-loop process.

Connect PLM and IoT with closed-loop process

Connecting the virtual product model via the physical product and its digital twin opens up all the possibilities of innovative product development. Create a closed-loop process through PLM and IoT along the entire Digital Thread. This allows you to plan, develop and continuously improve current products and upcoming product generations based on usage data!

Use smart product models along the Digital Thread and connect PLM and IoT

The engine for consistent PLM is the comprehensive model of the virtual product. This allows data and processes to be used digitally from the initial ideas through to release into production. Smart digital models simplify front-loading to make faster decisions and avoid late, costly changes. By enriching PLM data for downstream processes such as manufacturing and operations, you lay the foundation for an intelligent closed-loop process.

Connect PLM and IoT with closed-loop process

Connecting the virtual product model via the physical product and its digital twin opens up all the possibilities of innovative product development. Create a closed-loop process through PLM and IoT along the entire Digital Thread. This allows you to plan, develop and continuously improve current products and upcoming product generations based on usage data!

The engine for consistent PLM is the comprehensive model of the virtual product. This allows data and processes to be used digitally from the initial ideas through to release into production. Smart digital models simplify front-loading to make faster decisions and avoid late, costly changes. By enriching PLM data for downstream processes such as manufacturing and operations, you lay the foundation for an intelligent closed-loop process.

Connect PLM and IoT with closed-loop process

Connecting the virtual product model via the physical product and its digital twin opens up all the possibilities of innovative product development. Create a closed-loop process through PLM and IoT along the entire Digital Thread. This allows you to plan, develop and continuously improve current products and upcoming product generations based on usage data!

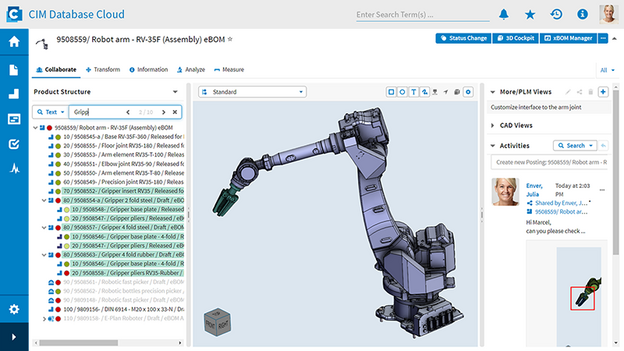

Encourage collaboration and share documents and knowledge

Efficient, trouble-free collaboration is the key for the development of demanding products and the harmonization of complex processes. With the “single source of truth” principle, your employees all access the same information and share their knowledge throughout your enterprise. To make this possible, they benefit from high-performance integrations for Microsoft Office, e-mail and CAD, viewing capabilities for all commonly used Office, CAD and multimedia formats, reliable change and release procedures and high-speed search functions through the entire data stock. This speeds up your work processes, minimizes search and archiving activities and ensures reliable know-how protection.

Encourage collaboration and share documents and knowledge

Efficient, trouble-free collaboration is the key for the development of demanding products and the harmonization of complex processes. With the “single source of truth” principle, your employees all access the same information and share their knowledge throughout your enterprise. To make this possible, they benefit from high-performance integrations for Microsoft Office, e-mail and CAD, viewing capabilities for all commonly used Office, CAD and multimedia formats, reliable change and release procedures and high-speed search functions through the entire data stock. This speeds up your work processes, minimizes search and archiving activities and ensures reliable know-how protection.

Efficient, trouble-free collaboration is the key for the development of demanding products and the harmonization of complex processes. With the “single source of truth” principle, your employees all access the same information and share their knowledge throughout your enterprise. To make this possible, they benefit from high-performance integrations for Microsoft Office, e-mail and CAD, viewing capabilities for all commonly used Office, CAD and multimedia formats, reliable change and release procedures and high-speed search functions through the entire data stock. This speeds up your work processes, minimizes search and archiving activities and ensures reliable know-how protection.

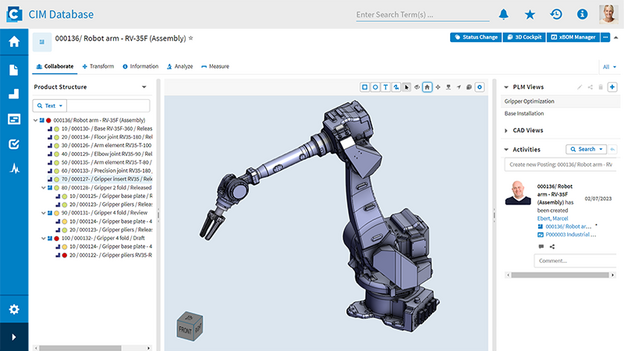

Run your PLM-processes quickly and reliably with best practices and templates

The consistent definition and execution of best practices makes processes more efficient and safer in terms of compliance management. CIM Database supports companies in mapping their best practices to project and process templates and executing them directly. The advantage: Reliability and proven, efficient interaction of employees in day-to-day business.

Make consistent use of workflows, status networks and tasks

Product development characteristically involves a high level of shared, parallel work. The starting point for improving process efficiency is therefore to replace manual processes and ineffective process interactions with digital procedures. This includes the synchronization of associated tasks with workflows and the qualification of the results through status networks. At the same time, your employees benefit from integrated task management and direct access to all the information they need for their tasks.

Run your PLM-processes quickly and reliably with best practices and templates

The consistent definition and execution of best practices makes processes more efficient and safer in terms of compliance management. CIM Database supports companies in mapping their best practices to project and process templates and executing them directly. The advantage: Reliability and proven, efficient interaction of employees in day-to-day business.

Make consistent use of workflows, status networks and tasks

Product development characteristically involves a high level of shared, parallel work. The starting point for improving process efficiency is therefore to replace manual processes and ineffective process interactions with digital procedures. This includes the synchronization of associated tasks with workflows and the qualification of the results through status networks. At the same time, your employees benefit from integrated task management and direct access to all the information they need for their tasks.

The consistent definition and execution of best practices makes processes more efficient and safer in terms of compliance management. CIM Database supports companies in mapping their best practices to project and process templates and executing them directly. The advantage: Reliability and proven, efficient interaction of employees in day-to-day business.

Make consistent use of workflows, status networks and tasks

Product development characteristically involves a high level of shared, parallel work. The starting point for improving process efficiency is therefore to replace manual processes and ineffective process interactions with digital procedures. This includes the synchronization of associated tasks with workflows and the qualification of the results through status networks. At the same time, your employees benefit from integrated task management and direct access to all the information they need for their tasks.

Combine project management and processing methodically perfect

With Agile Methods, CIM Database makes it possible to ideally combine control and execution in projects. Every member of staff along the entire product lifecycle benefits from its integrated project functions.

Product development is an agile project undertaking. The key challenge lies in responding to changes within the bounds of a reliable framework. To make this possible, you need functions that permit changes to be made both bottom-up and top-down. Project structure plans, schedules, quality gates, checklists and deliverables are established planning and control instruments. CIM Database combines them intelligently with the functions for agile work by employees and teams working largely on their own responsibility.

Combine project management and processing methodically perfect

With Agile Methods, CIM Database makes it possible to ideally combine control and execution in projects. Every member of staff along the entire product lifecycle benefits from its integrated project functions.

Product development is an agile project undertaking. The key challenge lies in responding to changes within the bounds of a reliable framework. To make this possible, you need functions that permit changes to be made both bottom-up and top-down. Project structure plans, schedules, quality gates, checklists and deliverables are established planning and control instruments. CIM Database combines them intelligently with the functions for agile work by employees and teams working largely on their own responsibility.

With Agile Methods, CIM Database makes it possible to ideally combine control and execution in projects. Every member of staff along the entire product lifecycle benefits from its integrated project functions.

Product development is an agile project undertaking. The key challenge lies in responding to changes within the bounds of a reliable framework. To make this possible, you need functions that permit changes to be made both bottom-up and top-down. Project structure plans, schedules, quality gates, checklists and deliverables are established planning and control instruments. CIM Database combines them intelligently with the functions for agile work by employees and teams working largely on their own responsibility.

Connect systems containing up-to-the-minute data throughout the enterprise

CAD data such as 3D models, drawings and circuit diagrams is a key source of information in the development process. With CONTACT Workspaces, you benefit from outstanding CAD and multi-CAD data management for better collaboration and reliable processes that interact with the PLM backbone. Workspaces also allows you to ensure cross-enterprise collaboration with partners and suppliers. It enables you to exchange CAD and product data faster and more reliably.

Connect enterprise systems with Catalyst

The open, service-oriented architecture of CIM Database ensures the end-to-end consistency of business processes during their interactions with other enterprise-wide IT systems such as SAP. The application's capabilities range from the transfer of articles and BOMs, through the synchronization of document and project data and on to the parallel provisioning of data to multiple ERP systems. Catalyst supports process-based data exchange and interaction with other enterprise sytems in an event-driven manner using the publisher-subscriber model. For example, this ensures that changes to product data are automatically shared with ERP systems.

Connect systems containing up-to-the-minute data throughout the enterprise

CAD data such as 3D models, drawings and circuit diagrams is a key source of information in the development process. With CONTACT Workspaces, you benefit from outstanding CAD and multi-CAD data management for better collaboration and reliable processes that interact with the PLM backbone. Workspaces also allows you to ensure cross-enterprise collaboration with partners and suppliers. It enables you to exchange CAD and product data faster and more reliably.

Connect enterprise systems with Catalyst

The open, service-oriented architecture of CIM Database ensures the end-to-end consistency of business processes during their interactions with other enterprise-wide IT systems such as SAP. The application's capabilities range from the transfer of articles and BOMs, through the synchronization of document and project data and on to the parallel provisioning of data to multiple ERP systems. Catalyst supports process-based data exchange and interaction with other enterprise sytems in an event-driven manner using the publisher-subscriber model. For example, this ensures that changes to product data are automatically shared with ERP systems.

CAD data such as 3D models, drawings and circuit diagrams is a key source of information in the development process. With CONTACT Workspaces, you benefit from outstanding CAD and multi-CAD data management for better collaboration and reliable processes that interact with the PLM backbone. Workspaces also allows you to ensure cross-enterprise collaboration with partners and suppliers. It enables you to exchange CAD and product data faster and more reliably.

Connect enterprise systems with Catalyst

The open, service-oriented architecture of CIM Database ensures the end-to-end consistency of business processes during their interactions with other enterprise-wide IT systems such as SAP. The application's capabilities range from the transfer of articles and BOMs, through the synchronization of document and project data and on to the parallel provisioning of data to multiple ERP systems. Catalyst supports process-based data exchange and interaction with other enterprise sytems in an event-driven manner using the publisher-subscriber model. For example, this ensures that changes to product data are automatically shared with ERP systems.

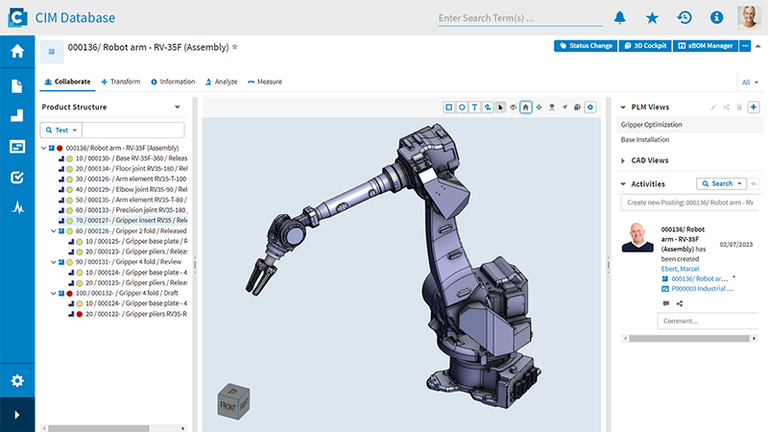

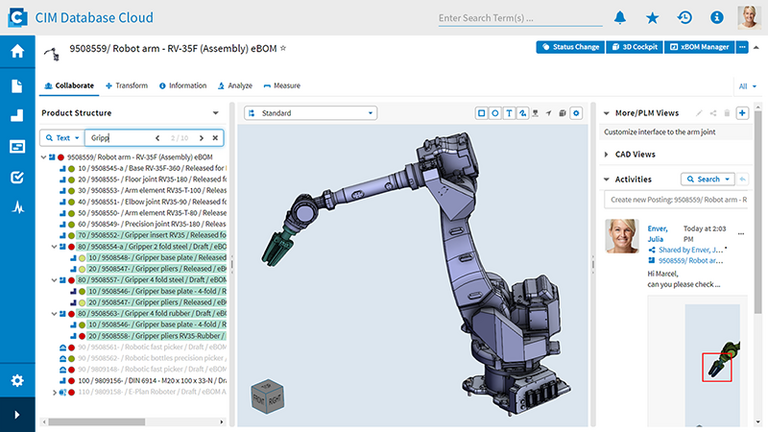

Choose the best operating mode for you – On-Premises or Cloud

You have the choice – our top-class PLM software is available in two operating modes: On-Premises or Cloud. If you opt for our Cloud offering, you will benefit from all the proven advantages of CIM Database combined with the power of cloud technology.

CIM Database Cloud is optimized as ready-to-run software for quick deployment, combining enterprise PLM functionality with the performance, scalability, and security of the cloud. With CIM Database Cloud, you can get started easily and quickly, growing at your own pace.

Choose the best operating mode for you – On-Premises or Cloud

You have the choice – our top-class PLM software is available in two operating modes: On-Premises or Cloud. If you opt for our Cloud offering, you will benefit from all the proven advantages of CIM Database combined with the power of cloud technology.

CIM Database Cloud is optimized as ready-to-run software for quick deployment, combining enterprise PLM functionality with the performance, scalability, and security of the cloud. With CIM Database Cloud, you can get started easily and quickly, growing at your own pace.

You have the choice – our top-class PLM software is available in two operating modes: On-Premises or Cloud. If you opt for our Cloud offering, you will benefit from all the proven advantages of CIM Database combined with the power of cloud technology.

CIM Database Cloud is optimized as ready-to-run software for quick deployment, combining enterprise PLM functionality with the performance, scalability, and security of the cloud. With CIM Database Cloud, you can get started easily and quickly, growing at your own pace.

Measure your Product Carbon Footprint

Calculating the Product Carbon Footprint (PCF) is a crucial initial step for companies to identify measures to reduce greenhouse gas emissions and to make progress quantifiable. CONTACT Elements facilitates the determination of product emissions, enabling effective emission monitoring throughout development phases and disciplines, thanks to powerful functionalities and insightful reporting. Utilize our Product Carbon Footprint Software to capture environmental data, identify emission-intensive components and processes, and implement targeted emission reduction strategies right from the product design phase.

Measure your Product Carbon Footprint

Calculating the Product Carbon Footprint (PCF) is a crucial initial step for companies to identify measures to reduce greenhouse gas emissions and to make progress quantifiable. CONTACT Elements facilitates the determination of product emissions, enabling effective emission monitoring throughout development phases and disciplines, thanks to powerful functionalities and insightful reporting. Utilize our Product Carbon Footprint Software to capture environmental data, identify emission-intensive components and processes, and implement targeted emission reduction strategies right from the product design phase.

Calculating the Product Carbon Footprint (PCF) is a crucial initial step for companies to identify measures to reduce greenhouse gas emissions and to make progress quantifiable. CONTACT Elements facilitates the determination of product emissions, enabling effective emission monitoring throughout development phases and disciplines, thanks to powerful functionalities and insightful reporting. Utilize our Product Carbon Footprint Software to capture environmental data, identify emission-intensive components and processes, and implement targeted emission reduction strategies right from the product design phase.

CIM Database is tool qualified for ISO 26262 standards

CONTACT Elements is tool-qualified by TÜV Nord according to ISO 26262. In addition to the CONTACT Elements platform, the international technology expert for security has certified the products CIM Database for PLM and Project Office for project management, as well as a number of CONTACT Elements software modules. With this certification, TÜV Nord assures that our software meets the requirements of ISO 26262 for standards for software tools for the development of safety-relevant properties.

Everything for your PLM initiative – powered by CONTACT Elements

Powered by CONTACT Elements means: You use the world's most up-to-date platform and technology for the data management of virtual products, collaboration, and process and project management in the product engineering environment. CIM Database helps you do this with a comprehensive application portfolio and a range of best practices. CONTACT Elements' flexible modular design principle stands for solutions that are far more than the sum of their parts: each impressive in its own right – combined outstanding!

Get to know the CIM Database applications better!

You want to learn more about CIM Database PLM?

Find out more from our current news and informations. Choose elements from the most interesting sections.