Greenhouse gas emissions along the product life cycle

The responsible use of resources is one of the greatest challenges of our time. Companies are called upon to actively reduce emissions and meet increasing sustainability reporting requirements. The measurement of greenhouse gas emissions is already mandated by current guidelines such as the Corporate Sustainability Reporting Directive (CSRD). Calculating the Product Carbon Footprint (PCF) throughout the entire product lifecycle is a crucial step for companies to meet these reporting requirements, as well as the rising customer demands for price, quality, and sustainability.

With CONTACT Elements, you can precisely determine your product emissions. Powerful features and insightful reporting enable effective emissions monitoring across development phases and disciplines. Capture environmental information with our Product Carbon Footprint Software and identify components and processes with high emissions. Implement emission-reducing measures directly in product design.

Advantages of Product Carbon Footprint Software

- Determine product and variant emissions with bills of materials

- Gain decision-making foundations for product development

- Ensure transparency and data sovereignty

- Make sustainable supplier selections

- Create standard-compliant accounting and reporting

Assessing environmental factors with materials & compliance management

High prices of raw materials, shortages of precursors, and increasing sustainability requirements significantly impact production planning. To prevent production lines from coming to a stop, it is crucial to enhance the resilience of supply chains. At the same time, there is a growing emphasis from both customers and legislators on the environmental footprint of products. The CONTACT Elements platform offers an innovative component in sustainable Product Lifecycle Management (PLM) with Material Data Management. This enables companies to manage materials sustainably and flexibly as well as responding to new requirements such as the quick identification of alternative materials.

Assessing environmental factors with materials & compliance management

High prices of raw materials, shortages of precursors, and increasing sustainability requirements significantly impact production planning. To prevent production lines from coming to a stop, it is crucial to enhance the resilience of supply chains. At the same time, there is a growing emphasis from both customers and legislators on the environmental footprint of products. The CONTACT Elements platform offers an innovative component in sustainable Product Lifecycle Management (PLM) with Material Data Management. This enables companies to manage materials sustainably and flexibly as well as responding to new requirements such as the quick identification of alternative materials.

High prices of raw materials, shortages of precursors, and increasing sustainability requirements significantly impact production planning. To prevent production lines from coming to a stop, it is crucial to enhance the resilience of supply chains. At the same time, there is a growing emphasis from both customers and legislators on the environmental footprint of products. The CONTACT Elements platform offers an innovative component in sustainable Product Lifecycle Management (PLM) with Material Data Management. This enables companies to manage materials sustainably and flexibly as well as responding to new requirements such as the quick identification of alternative materials.

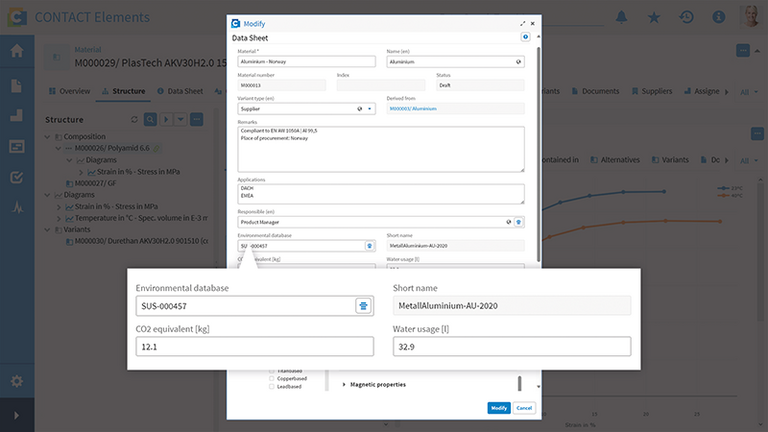

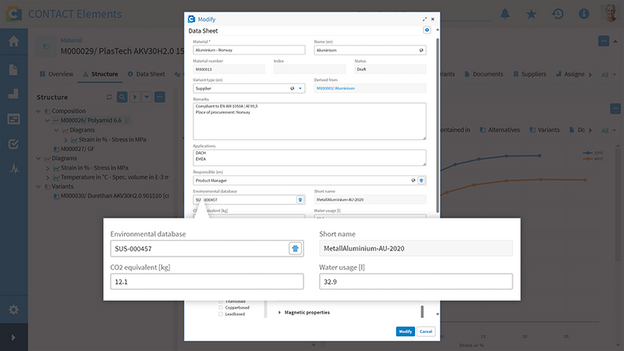

Environmental data management – integration of lifecycle assessment databases

The integration of lifecycle assessment databases represents a significant step towards a comprehensive consideration of ecological aspects throughout the entire product lifecycle. It significantly improves the availability and quality of data, aiding in optimizing the sustainability of products from the early design phase through manufacturing to disposal.

Environmental data management – integration of lifecycle assessment databases

The integration of lifecycle assessment databases represents a significant step towards a comprehensive consideration of ecological aspects throughout the entire product lifecycle. It significantly improves the availability and quality of data, aiding in optimizing the sustainability of products from the early design phase through manufacturing to disposal.

The integration of lifecycle assessment databases represents a significant step towards a comprehensive consideration of ecological aspects throughout the entire product lifecycle. It significantly improves the availability and quality of data, aiding in optimizing the sustainability of products from the early design phase through manufacturing to disposal.

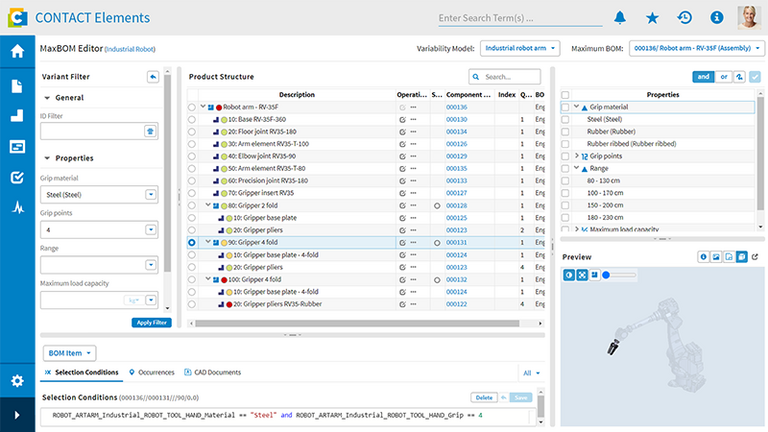

Sustainability-related assessment with Bill of Materials

Connecting environmental metrics with product bill of materials in the PLM system enables the precise analysis of environmental impacts at each stage of development. Through this integrated approach, companies can identify "hotspots" where most emissions occur and make informed decisions to minimize environmental impacts. The calculation is based on recognized standards such as ISO 14067 and the Greenhouse Gas Protocol. In addition to emissions analysis, cost factors can also be considered to promote cost-efficient and environmentally friendly product development.

Sustainability-related assessment with Bill of Materials

Connecting environmental metrics with product bill of materials in the PLM system enables the precise analysis of environmental impacts at each stage of development. Through this integrated approach, companies can identify "hotspots" where most emissions occur and make informed decisions to minimize environmental impacts. The calculation is based on recognized standards such as ISO 14067 and the Greenhouse Gas Protocol. In addition to emissions analysis, cost factors can also be considered to promote cost-efficient and environmentally friendly product development.

Connecting environmental metrics with product bill of materials in the PLM system enables the precise analysis of environmental impacts at each stage of development. Through this integrated approach, companies can identify "hotspots" where most emissions occur and make informed decisions to minimize environmental impacts. The calculation is based on recognized standards such as ISO 14067 and the Greenhouse Gas Protocol. In addition to emissions analysis, cost factors can also be considered to promote cost-efficient and environmentally friendly product development.

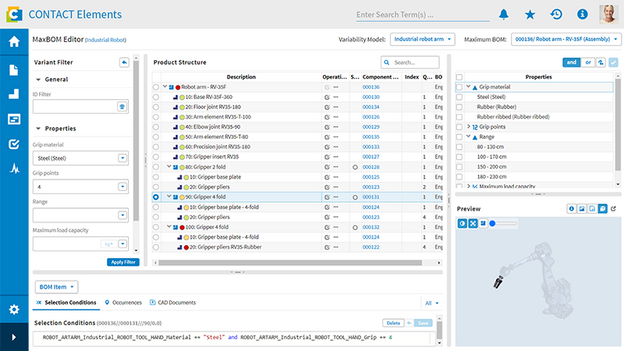

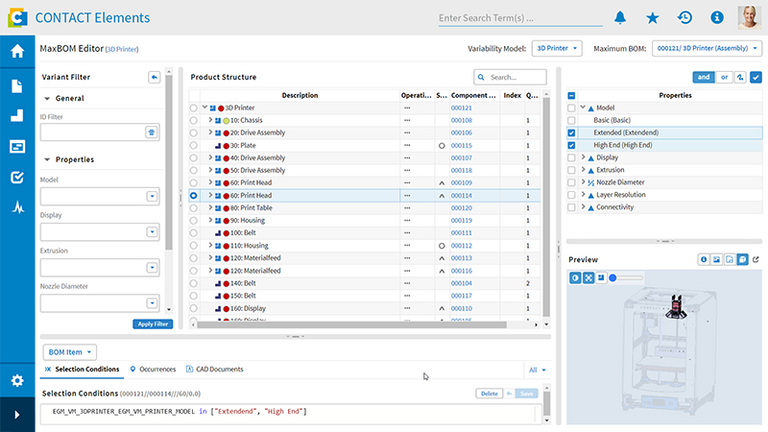

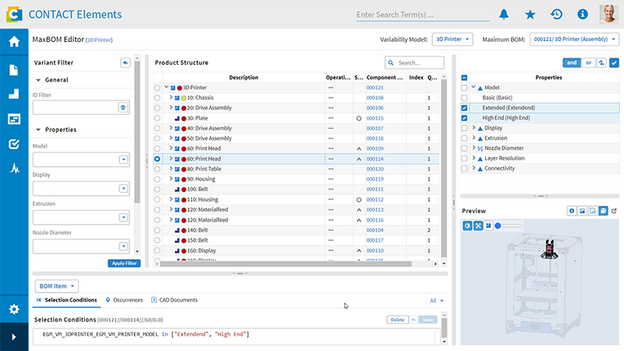

Efficient variant management for a sustainable product portfolio

Through the systematic assessment and evaluation of sustainable alternatives for product variants, environmental impacts can be analyzed in different scenarios. This can be achieved through efficient and sustainable variant management, which also supports the calculation of environmental impacts across the portfolio. This allows priorities to be identified and shaped in order to optimize portfolio management systematically.

Efficient variant management for a sustainable product portfolio

Through the systematic assessment and evaluation of sustainable alternatives for product variants, environmental impacts can be analyzed in different scenarios. This can be achieved through efficient and sustainable variant management, which also supports the calculation of environmental impacts across the portfolio. This allows priorities to be identified and shaped in order to optimize portfolio management systematically.

Through the systematic assessment and evaluation of sustainable alternatives for product variants, environmental impacts can be analyzed in different scenarios. This can be achieved through efficient and sustainable variant management, which also supports the calculation of environmental impacts across the portfolio. This allows priorities to be identified and shaped in order to optimize portfolio management systematically.

Transparency and data sovereignty within the value chain

A robust data infrastructure and transparency in the value chain are crucial for a sustainable and circular economy. Regulatory requirements for reporting and sharing sustainability information are increasing. An integrated approach towards sustainability-oriented product lifecycle management supports the creation of Environmental Product Declarations (EPDs) for both individual products and variants within the product portfolio. Established standards like the Asset Administration Shell enable the overcoming of data silos to exchange high-quality sustainability data across the entire value chain.

Transparency and data sovereignty within the value chain

A robust data infrastructure and transparency in the value chain are crucial for a sustainable and circular economy. Regulatory requirements for reporting and sharing sustainability information are increasing. An integrated approach towards sustainability-oriented product lifecycle management supports the creation of Environmental Product Declarations (EPDs) for both individual products and variants within the product portfolio. Established standards like the Asset Administration Shell enable the overcoming of data silos to exchange high-quality sustainability data across the entire value chain.

A robust data infrastructure and transparency in the value chain are crucial for a sustainable and circular economy. Regulatory requirements for reporting and sharing sustainability information are increasing. An integrated approach towards sustainability-oriented product lifecycle management supports the creation of Environmental Product Declarations (EPDs) for both individual products and variants within the product portfolio. Established standards like the Asset Administration Shell enable the overcoming of data silos to exchange high-quality sustainability data across the entire value chain.

Related Elements

Calculate product costs to ensure that the price is right

Calculate product variants and their costs quickly and efficiently

Plan sales targets for optimum costing and increase the profitability of your products

Focus on your objectives to keep your project costs in budget

Manage material information across the enterprise and ensure sustainability

Company-wide availability of detailed information on material properties

Smooth teamwork with reliable material data

Rapid identification of alternative materials

Ensure sustainability and compliance

Seamlessly integrate design and operations of smart products

Analyze and evaluate field data for targeted product enhancements

Involve your customer communities in the ongoing optimization of your products

Use tried-and-tested procedures such as ticket systems and engineering change management for integration in your development processes

Intelligent data sharing for end-to-end processes across organizational boundaries

Reliable collaboration through data sharing

Collaboration environment designed for engineering processes

Data usage across system boundaries

Extensive security and compliance mechanisms

Greater clarity when controlling product and project portfolios

Achieve systematic frontloading with the right ideas and initiatives

Structure your portfolios to achieve greater clarity

Inspect projects at the touch of a button throughout the entire lifecycle

Further information

Would you like to find out more about this topic? Choose one of the following information offers.