Integrate environmental data from heterogenous systems into PLM

Sustainability reporting is shifting from a nice-to-have to a must-have. Legislators like the EU are driving green initiatives that result in comprehensive reporting obligations for companies. At the same time, market pressure is rising, as customers demand reliable sustainability metrics from their suppliers. To meet these requirements, you need software that consolidates information from heterogeneous sources and transforms it into meaningful reports and KPIs.

80 percent of a product’s environmental footprint is determined during its development. Sustainability information therefore has its greatest impact in the PLM system, where product data, projects, and processes converge. Right here, the CONTACT Elements integration platform enables you to lay the groundwork for an end-to-end Green Digital Thread which can be extended from design to manufacturing and the operation of machinery, plants, and building technology.

Consulting for long-term vision and quick wins

Sustainability requires more than just good software. The key is a three-pillar approach: technology, process consulting, and a sound implementation concept. As your digitalization partner, we guide you on the path to a data-driven, compliance-aligned sustainability strategy. Together, we assess your status quo and develop a structured roadmap that you can implement at your own pace with the modular Elements platform. The result: a long-term vision combined with immediate, tangible successes.

Consolidate your green data

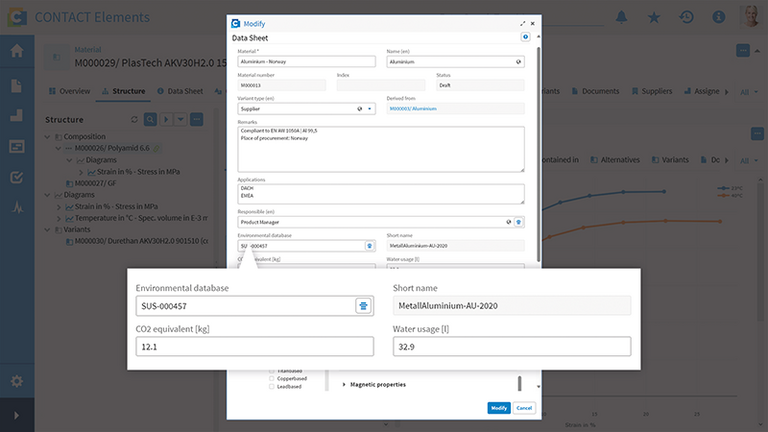

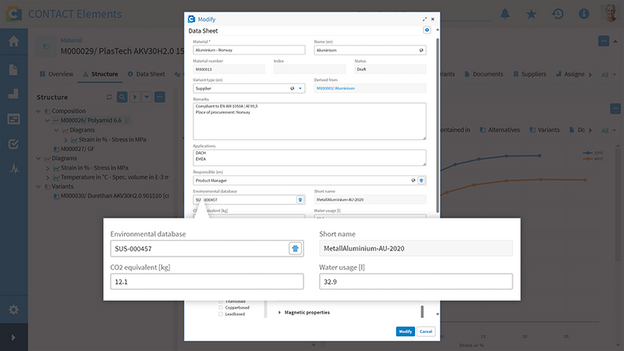

To effectively utilize environmental data, it must be centrally accessible and of high quality. CONTACT Elements provides the ideal foundation for this: The integration platform is based on open standards like HTML5, REST, and Python. It can seamlessly synchronize data from third-party systems via powerful interface technology – whether from your own IT landscape, suppliers, or external environmental databases. Integrated AI applications support you in structuring the data and evaluating its quality.

Whether it’s automated reporting to meet legal requirements, calculating relevant key metrics for customers, or analyzing the Product Carbon Footprint (PCF) of different design alternatives during development – our specialized sustainability applications help you get the most out of your sustainability data.

Consolidate your green data

To effectively utilize environmental data, it must be centrally accessible and of high quality. CONTACT Elements provides the ideal foundation for this: The integration platform is based on open standards like HTML5, REST, and Python. It can seamlessly synchronize data from third-party systems via powerful interface technology – whether from your own IT landscape, suppliers, or external environmental databases. Integrated AI applications support you in structuring the data and evaluating its quality.

Whether it’s automated reporting to meet legal requirements, calculating relevant key metrics for customers, or analyzing the Product Carbon Footprint (PCF) of different design alternatives during development – our specialized sustainability applications help you get the most out of your sustainability data.

To effectively utilize environmental data, it must be centrally accessible and of high quality. CONTACT Elements provides the ideal foundation for this: The integration platform is based on open standards like HTML5, REST, and Python. It can seamlessly synchronize data from third-party systems via powerful interface technology – whether from your own IT landscape, suppliers, or external environmental databases. Integrated AI applications support you in structuring the data and evaluating its quality.

Whether it’s automated reporting to meet legal requirements, calculating relevant key metrics for customers, or analyzing the Product Carbon Footprint (PCF) of different design alternatives during development – our specialized sustainability applications help you get the most out of your sustainability data.

Anchor sustainability in PLM

Learn how to document and reduce the environmental impact of your products with CONTACT Elements in the commentary by consulting firm CIMdata.

Extend your Green Digital Thread

Thanks to application modules for the Internet of Things (IoT), you can extend CONTACT Elements into areas such as manufacturing, asset management, and service. The platform is ideal for establishing an energy management system compliant with ISO 50001, which is state-subsidized in some countries. It captures and visualizes the energy consumption of your facilities and buildings in real-time. Your company implements Digital Twins of energy-intensive machinery and assets, creating a foundation for sustainable energy savings. You identify potential savings, generate audit-ready reports, and – by combining this data with production information – strategically mitigate load peaks.

Extend your Green Digital Thread

Thanks to application modules for the Internet of Things (IoT), you can extend CONTACT Elements into areas such as manufacturing, asset management, and service. The platform is ideal for establishing an energy management system compliant with ISO 50001, which is state-subsidized in some countries. It captures and visualizes the energy consumption of your facilities and buildings in real-time. Your company implements Digital Twins of energy-intensive machinery and assets, creating a foundation for sustainable energy savings. You identify potential savings, generate audit-ready reports, and – by combining this data with production information – strategically mitigate load peaks.

Thanks to application modules for the Internet of Things (IoT), you can extend CONTACT Elements into areas such as manufacturing, asset management, and service. The platform is ideal for establishing an energy management system compliant with ISO 50001, which is state-subsidized in some countries. It captures and visualizes the energy consumption of your facilities and buildings in real-time. Your company implements Digital Twins of energy-intensive machinery and assets, creating a foundation for sustainable energy savings. You identify potential savings, generate audit-ready reports, and – by combining this data with production information – strategically mitigate load peaks.

We’re driving sustainability in industry

In 2019, CONTACT established a research team dedicated to topics such as sustainability, AI solutions for engineering, and the future of manufacturing. In close collaboration with experts from industry and academia, the team works on research projects whose priorities align with political initiatives like Industry 4.0 or the European Green Deal. These projects encompass applied research as well as the development of technologies and methods that help the industry design and manufacture more efficiently and sustainably.

Further information

Would you like to find out more about this topic? Choose one of the following information offers.