Getting to grips with the challenges posed by the digital transformation is placing enormous pressure on companies. This is often due in part to outdated processes and IT systems. Nevertheless, many companies shy away from switching to more powerful solutions due to high costs and risks involved. Migration in particular can become complicated. Hundreds of thousands of complexly structured data sets such as CAD models, BOMs and project structures have to be mapped reliably.

Migrating data from existing systems is part of our day-to-day business. We have bundled the extensive know-how gained from hundreds of projects in our Smooth Migration Methodology, which allows well-known systems such as Pro.File, keytech PLM/DMS, Oracle Agile PLM, SmarTeam, Creo Elements/Direct Model Manager and ProductStream Professional (PSP) to be replaced with state-of-the-art processes and technologies.

How to smoothly switch to a new system

Tailored to the way a company works

We start by analyzing your existing system. This is followed by in-depth strategy consulting. When it comes to exporting the data, we work together with partners who are experts in dealing with the respective proprietary CAD systems. All this makes it possible for us to focus on your individual circumstances, which provides us with a solid basis for recommending an appropriate migration methodology. Depending on your requirements and the risks involved, we decide together with you whether it is best to switch systems in one fell swoop (big bang) or a gradually, step-by-step.

A methodical approach ensures reliability

We perform migration in close coordination with you based on a requirements specification and clearly defined areas of responsibility. Standardized processes reduce the time and effort involved in the project and ensure secure and transparent workflows. We provide you with advice on the methodology best suited to implement the project. We will recommend either an agile, hybrid approach or a more classic approach, depending what makes the most sense. In the case of extremely complex migrations, we also offer the option of temporarily operating the old and new system in parallel.

Efficiency and control thanks to a high level of automation

Our specialized technology partners export the data using migration toolkits and ensure the reliable replacement of third-party systems and conversion to standard CONTACT formats. The toolkits make it possible to automatically exchange individual data sets or large quantities of data. When the data is imported into the CONTACT target system, templates are used to control the import of certain object types and generic components for transformation rules.

VEMAG chooses greater agility

VEMAG is a leading manufacturer of machines for the food industry. Growing demands from the food sector and consumers as well as strict legal requirements require fast and flexible innovation processes. The company selected CIM Database with the aim of enhancing its competitive capabilities and supporting the agility required in this dynamic market. The previous Oracle Agile PLM system was thus replaced by CONTACT's PLM system.

VEMAG chooses greater agility

VEMAG is a leading manufacturer of machines for the food industry. Growing demands from the food sector and consumers as well as strict legal requirements require fast and flexible innovation processes. The company selected CIM Database with the aim of enhancing its competitive capabilities and supporting the agility required in this dynamic market. The previous Oracle Agile PLM system was thus replaced by CONTACT's PLM system.

VEMAG is a leading manufacturer of machines for the food industry. Growing demands from the food sector and consumers as well as strict legal requirements require fast and flexible innovation processes. The company selected CIM Database with the aim of enhancing its competitive capabilities and supporting the agility required in this dynamic market. The previous Oracle Agile PLM system was thus replaced by CONTACT's PLM system.

Kiekert's global "big bang"

Kiekert has replaced the SmarTeam systems at all its development sites in one fell swoop (big bang). This move is intended to enable the manufacturer of automotive closure systems to provide the best possible support for its global development projects. Find out why Kiekert implemented CIM Database using an agile approach, how data from five systems was merged and which key performance indicators provide proof of the benefits of the new PLM applications since it went live.

Kiekert's global "big bang"

Kiekert has replaced the SmarTeam systems at all its development sites in one fell swoop (big bang). This move is intended to enable the manufacturer of automotive closure systems to provide the best possible support for its global development projects. Find out why Kiekert implemented CIM Database using an agile approach, how data from five systems was merged and which key performance indicators provide proof of the benefits of the new PLM applications since it went live.

Kiekert has replaced the SmarTeam systems at all its development sites in one fell swoop (big bang). This move is intended to enable the manufacturer of automotive closure systems to provide the best possible support for its global development projects. Find out why Kiekert implemented CIM Database using an agile approach, how data from five systems was merged and which key performance indicators provide proof of the benefits of the new PLM applications since it went live.

SIG Combibloc is switching systems

Together with SolidLine, CONTACT Software came out on top in a large-scale PLM benchmark. SIG Combibloc, one of the world's leading manufacturers of cartons and filling machines for food and beverages, has replaced Creo Elements/Direct Model Manager and completely reorganized its global product development process with CIM Database PLM and SolidWorks.

SIG Combibloc is switching systems

Together with SolidLine, CONTACT Software came out on top in a large-scale PLM benchmark. SIG Combibloc, one of the world's leading manufacturers of cartons and filling machines for food and beverages, has replaced Creo Elements/Direct Model Manager and completely reorganized its global product development process with CIM Database PLM and SolidWorks.

Together with SolidLine, CONTACT Software came out on top in a large-scale PLM benchmark. SIG Combibloc, one of the world's leading manufacturers of cartons and filling machines for food and beverages, has replaced Creo Elements/Direct Model Manager and completely reorganized its global product development process with CIM Database PLM and SolidWorks.

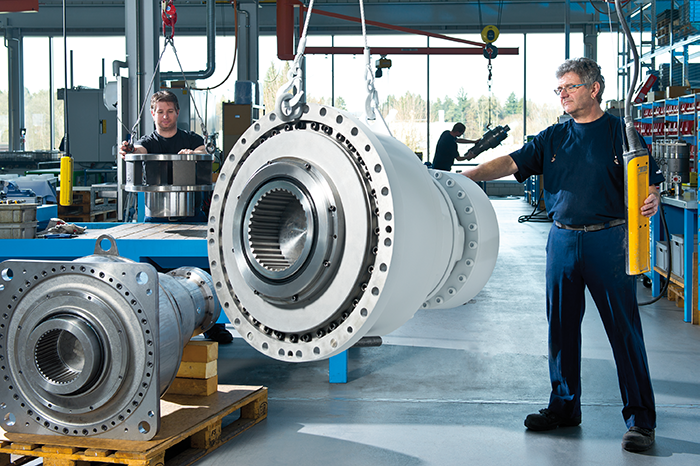

Swiss Rollstar AG opts for reliability

Drives have been Rollstar AG's hallmark on every continent in the world for 50 years. The go-live of CONTACT's PLM solution marked completion of the company's replacement of its legacy system Pro.File, thus ensuring that its product development processes are efficient and future-proof.

Swiss Rollstar AG opts for reliability

Drives have been Rollstar AG's hallmark on every continent in the world for 50 years. The go-live of CONTACT's PLM solution marked completion of the company's replacement of its legacy system Pro.File, thus ensuring that its product development processes are efficient and future-proof.

Drives have been Rollstar AG's hallmark on every continent in the world for 50 years. The go-live of CONTACT's PLM solution marked completion of the company's replacement of its legacy system Pro.File, thus ensuring that its product development processes are efficient and future-proof.

Using the challenges of digital transformation as an opportunity

IT systems are innovation drivers at best - and innovation dead ends at worst. Systems that can no longer be further developed slow down the innovation productivity of companies. However, many companies shy away from a system change because they fear that it will be risky, lengthy and expensive. We have bundled our extensive know-how from hundreds of projects into the Smooth Migration methodology. Learn how a system change works smoothly.

Your contact

Sales Manager South

Sales Manager North